Refinery Pumps

Refinery pumps are specialized pumps used in oil refineries, petrochemical plants, and chemical industries to transport crude oil and its derivatives. They operate within a temperature range of -120°C to +450°C and can handle pressures up to 65 bar. Due to the highly volatile and flammable nature of the fluids they handle, components in contact with the media are constructed from ductile materials such as:Unalloyed steel castings,Chromium steel castings,Ductile iron castings (less common)

Key Design Considerations

NPSHR (Net Positive Suction Head Required)

A critical factor in selecting drive motor speeds and pump configurations to avoid cavitation.

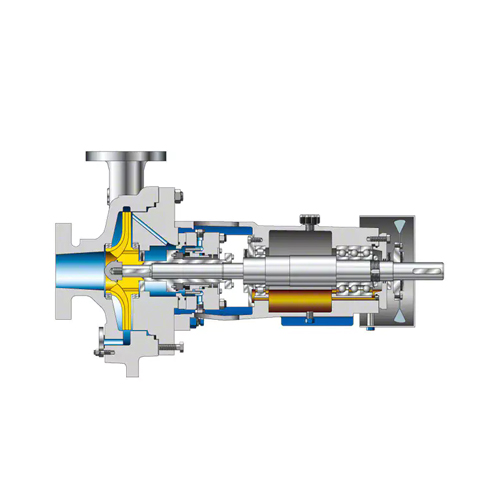

Common Pump Types:Single-Stage, Horizontal, Volute Casing Pumps (Back-Pull-Out Design)

Figure 1: Horizontal, Back-Pull-Out Refinery Pump

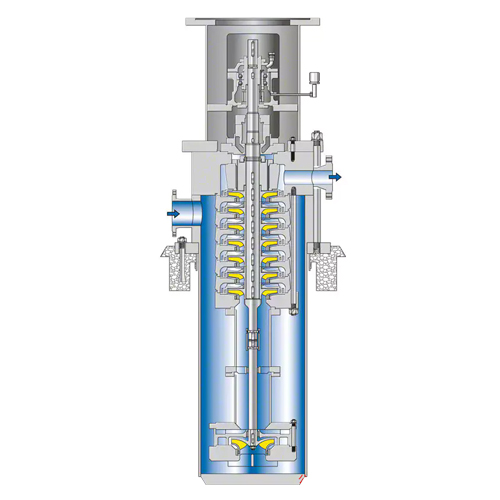

Vertical, Multistage, Barrel-Type Pumps (for low suction pressure or cryogenic conditions)

Figure 2: Vertical, Multistage, Barrel-Type, Seal-Less Refinery Pump

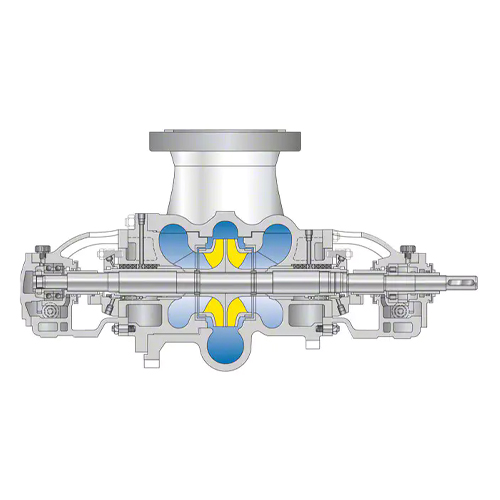

Horizontal, Double-Suction Pumps with Between-Bearing Support

Figure 3: Horizontal, Double-Suction Refinery Pump with Between-Bearing Support

Design Standards & Specifications

Refinery pumps must comply with stringent standards, including:

API 610 (American Petroleum Institute)

ISO 13709 (International Organization for Standardization)

These standards classify refinery pumps as "Heavy-Duty" due to their application in severe operating conditions.

Key Design Features per API 610/ISO 13709

Parameter | Design Requirements |

Support Type | Centerline-mounted or baseplate-mounted support based on operating temperatures. |

Nozzle Arrangement | End suction/top discharge, side suction/side discharge, or top suction/top discharge. |

Casing Split | Radially split or axially split. |

Sealing Systems | Mechanical seals with flushing plans (per API 682/ISO 21049). |

Bearing Cooling | Temperature limits enforced to prevent overheating. |

Standards: API 682 / ISO 21049 outline mechanical seal types, configurations, and flushing plans.

Flushing Plans: Include Plan 11 (internal recirculation), Plan 32 (external flush), and Plan 53 (pressurized dual seals).

Critical Design Challenges

High-Temperature Loads

Pipes in large refinery units exert significant forces and moments on pumps and baseplates.

Requirements:

Heavy-duty pumps and baseplates must absorb these loads without deformation beyond standard limits.

Materials and structural design must ensure stability under thermal expansion.

Material Selection

High-grade alloys (e.g., ASTM A487 CA6NM for impellers) for corrosion and erosion resistance.

Graphite-filled PTFE for high-temperature sealing.

Applications

Crude Oil Transfer: High-flow, low-pressure pumps.

Catalytic Cracking: High-temperature, abrasion-resistant designs.

Cryogenic Processing: Vertical barrel pumps for LNG and ethylene.