1. What is the Lomakin Effect?

The Lomakin effect, named after Soviet engineer Alexander Lomakin, refers to a phenomenon in pumps that affects the stability and operational behavior of fluid machinery, especially centrifugal pumps. It is particularly significant in terms of radial and axial thrust and hydraulic balance in pumps. For engineers and technicians involved in pump design, operation, and maintenance, understanding the Lomakin effect is crucial.

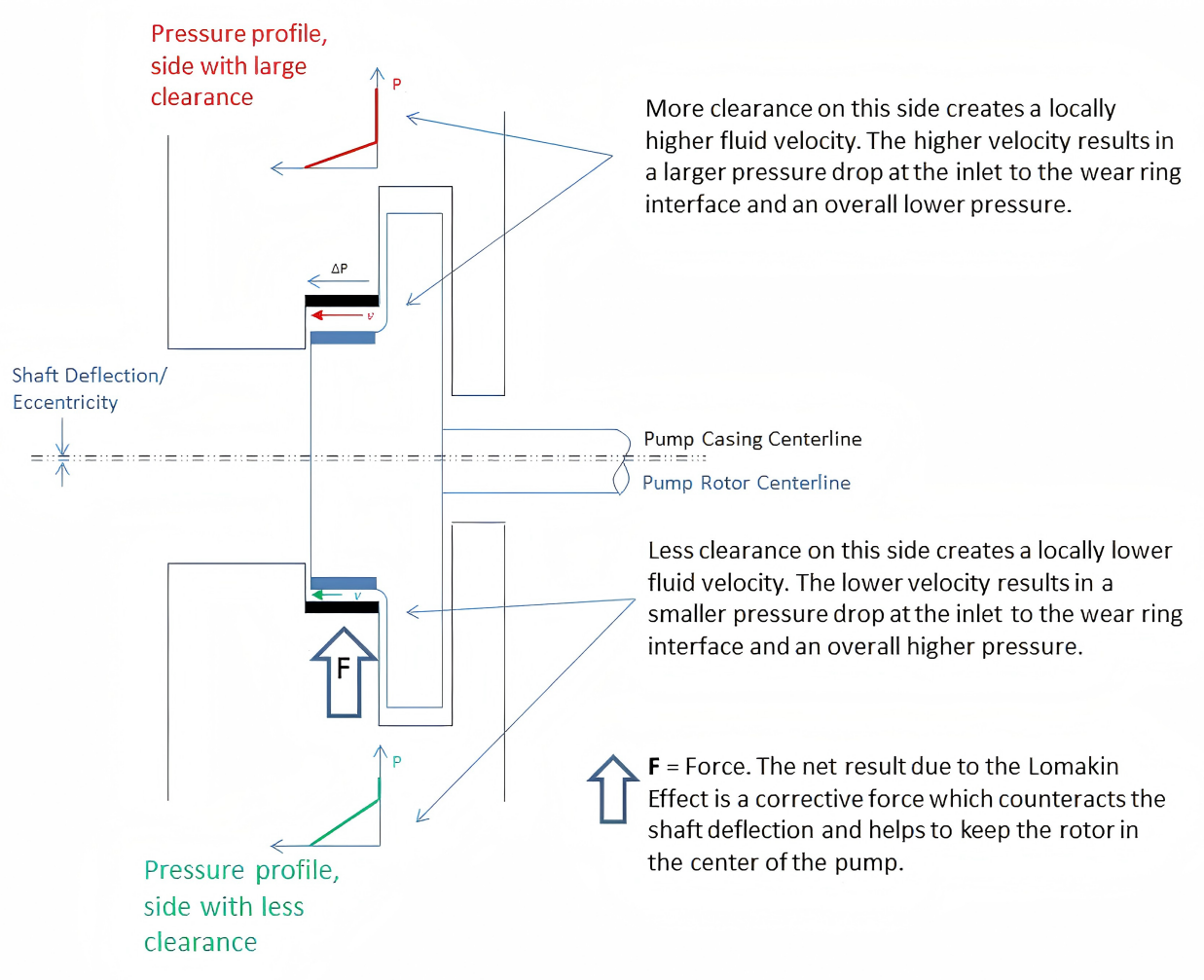

The Lomakin effect is the stabilizing force exerted on the pump rotor due to fluid pressure in the narrow gaps between the impeller and the pump casing, or between the shaft and stationary components such as wear rings, throttle bushings, or labyrinth seals. This pressure generates a radial force that resists the rotor's movement, thereby enhancing the pump's operational stability.

As shown in Figure 1, when fluid enters the gap between the rotor and the wear components, it accelerates as it flows from the high - pressure end to the low - pressure end. Due to the eccentricity of the rotor, the gap on one side of the wear ring is larger than the other. The side with the larger gap has a higher flow rate and a higher local velocity, while the side with the smaller gap has a lower velocity. According to the principle that higher velocity corresponds to lower pressure and lower velocity corresponds to higher pressure, this pressure difference creates a restoring force (net corrective force) in the direction opposite to the shaft deflection.

In other words, when the pump shaft deflects, a hydraulic "stiffness" (Lomakin stiffness) is generated to counteract this deflection. The Lomakin stiffness coefficient (Klomakin) of the wear ring or throttle bushing can be expressed by the following formula:

Klomakin=(RLΔP/c)K (N/mm)

where:

· R = Radius of the wear ring, mm

· L = Length of the wear ring, mm

· ΔP = Pressure difference across the wear ring, MPa

· c = Radial clearance, mm

· K= Dimensionless stiffness coefficient

In this formula, the only variable that can be easily controlled is the clearance. If the clearance of the wear ring is reduced by 50%, the Lomakin stiffness will double.

2. Working Principle of the Lomakin Effect

In a centrifugal pump, fluid under pressure is forced into the narrow gaps between the rotating and stationary parts of the pump. These narrow gaps are located at the wear rings, bushings, or labyrinth seals, where the Lomakin effect plays an important role. The working principle is as follows:

· Pressure Distribution: High - pressure fluid enters these gaps, creating a pressure difference on the rotor surface. This pressure difference exerts a force on the rotor in the direction opposite to any lateral (radial) displacement.

· Restoring Force: When the rotor tries to deviate from the center due to external interference, the pressure difference on the side with the narrower gap increases. This increased pressure generates a restoring force that pushes the rotor back to the center position.

· Damping and Stability: This effect can be regarded as a form of hydraulic damping, which reduces the amplitude of vibration and enhances the stability of the rotor. The Lomakin effect helps prevent excessive radial movement of the shaft and impeller, thereby reducing the risk of mechanical contact, wear, and failure.

3. Importance of the Lomakin Effect

The importance of the Lomakin effect is manifested in the following aspects:

· Stability of Rotating Components: The main advantage of the Lomakin effect is the stability of the rotating components (impeller and shaft) within the pump. This effect significantly reduces the possibility of contact between the rotating and stationary parts, thereby reducing wear, overheating, and even catastrophic failures.

· Reduction of Radial Vibration: By providing a centering force, the Lomakin effect minimizes radial vibration, avoiding premature failure of bearings, damage to seals, and a decrease in the overall reliability of the pump.

· Improvement of Pump Reliability: The stabilizing force provided by the Lomakin effect ensures smooth pump operation and reduces wear on important components, thereby significantly improving the long - term reliability of the pump.

4. Factors Affecting the Lomakin Effect

The main factors affecting the Lomakin effect include:

· Clearance Size: The size of the clearance between the impeller and the casing or between the shaft and the stationary components is the most important influencing factor. The smaller the clearance, the stronger the Lomakin effect; conversely, the larger the clearance, the weaker the Lomakin effect.

· Fluid Viscosity: The viscosity of the pumped fluid also has a certain impact on the effect. Higher - viscosity fluids can increase the stabilizing force because the flow resistance through the clearance is greater.

· Pressure Difference: The pressure difference across the clearance directly affects the strength of the Lomakin effect. The larger the pressure difference, the stronger the stabilizing force.

· Wear and Corrosion: Over time, wear and corrosion can cause the clearance between the moving and stationary parts of the pump to increase, thereby reducing the effectiveness of the Lomakin effect. Therefore, regular maintenance and inspection are crucial to keep the clearance within the design specifications.

5. Applications and Precautions

The Lomakin effect is of great significance in high - speed and high - pressure pumps because the forces acting on the rotor are large. Understanding and optimizing this effect is particularly important in the following situations:

· High - Performance Centrifugal Pumps: In applications where the pump operates at high speeds and pressures, the Lomakin effect is a key factor in ensuring that the rotor remains stable and centered.

· Multistage Pumps: In multistage pumps, the axial forces can be large, and the Lomakin effect helps balance these forces, thereby reducing the load on the thrust bearings.

· Pump Design and Maintenance: Engineers must carefully design the clearances and consider the Lomakin effect when selecting materials and specifying tolerances. In addition, regular maintenance is necessary to ensure that wear does not compromise the effectiveness of this stabilizing phenomenon.

6. Challenges and Limitations

Although the Lomakin effect has significant advantages, it also faces some challenges:

· Sensitivity to Clearance Changes: The effectiveness of the Lomakin effect is very sensitive to changes in clearance size. Even a small increase in clearance due to wear can significantly reduce the stabilizing force.

· Effect of Abrasive Fluids: In pumps handling abrasive fluids, the wear rate will increase, leading to an increase in clearance and a weakening of the Lomakin effect.

· Design Complexity: Optimizing the pump design for the Lomakin effect requires precise engineering design and a deep understanding of fluid dynamics. Balancing the need for tight clearances with the risk of mechanical contact and wear is a complex challenge.

Conclusion

The Lomakin effect is an important consideration in pump design, operation, and maintenance, especially in high - performance and high - pressure applications. It significantly improves the reliability and service life of the pump by providing a stabilizing force that centers the rotor and reduces vibration. Therefore, engineers and technicians working with centrifugal pumps must have a deep understanding of the various factors affecting this effect and the associated challenges.

Regular maintenance, careful design, and consideration of operating conditions are the keys to maximizing the advantages of the Lomakin effect and ensuring the long - term performance of the pumping system.