Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

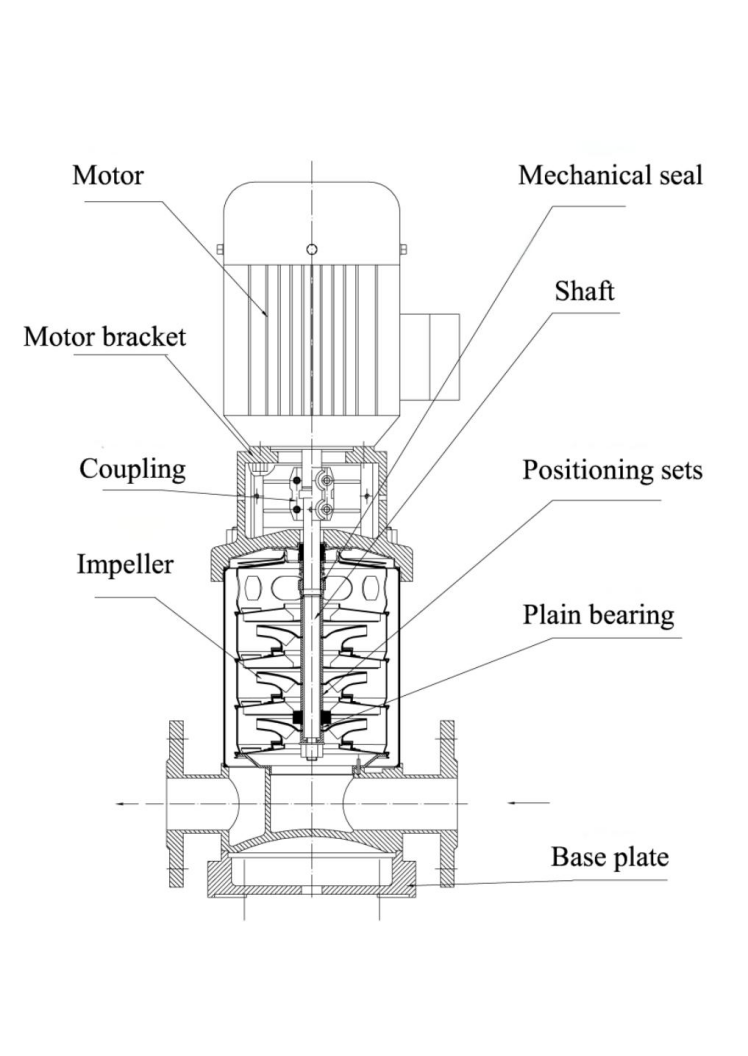

TPY Marine Stainless Steel Vertical Multistage Centrifugal Domestic Pump

Date:2025-03-07Views:

TPY Marine Stainless Steel Vertical Multistage Centrifugal Domestic Pump

Overview

TPY Series vertical multistage centrifugal pump, all material is stainless steel. For conveying the temperature between -40℃ to +120℃ of water, soft water, swimming pool water or slightly alkaline, and other stainless steel (304 or 316L) had no significant corrosion of the liquid, widely used in liquid transport, hot and cold clean water and softened water, mineral water and distilled off circulation and pressurization. Low noise, corrosion resistance, beautiful appearance, small size, smooth operation, easy installation, long service life.

Model Explanation TPY2-69

TPY—Stainless-steel vertical multi-stage centrifugal pump

2—Capacity 2 m3/h

67—Head 67 m

Structural Specifications

Product range (50HZ/380V)

Range | TPY1 | TPY2 | TPY3 | TPY4 | TPY5 | TPY8 | TPY12 | TPY16 | TPY20 |

Capacity (m3/h) | 1 | 2 | 3 | 4 | 5 | 8 | 12 | 16 | 20 |

Flow limitation(m3/h) | 0.6~2.0 | 1~3.5 | 1.2~4.0 | 2~8 | 2~8 | 5~12 | 7~16 | 8~22 | 10~28 |

Max pressure(bar) | 22 | 22 | 22 | 22 | 22 | 21 | 21 | 21 | 23 |

Motor power(kW) | 0.37~1.5 | 0.37~3 | 0.37~3 | 0.55~4 | 0.37~4 | 1.1~7.5 | 1.5~11 | 2.2~15 | 1.1~18.5 |

Maximum efficiency(%) | 48 | 48 | 57 | 60 | 62 | 63 | 63 | 68 | 69 |

Connections | |||||||||

Flange | DN25 | DN25 | DN25 | DN32 | DN32 | DN40 | DN40 | DN50 | DN50 |

Pipe thread | ZG11/4 | ZG11/4 | ZG11/4 | ZG11/4 | ZG11/4 | ZG11/2 | ZG11/2 | ZG2 | ZG2 |

Sleeve meet face | DN32 | DN32 | DN32 | DN32 | DN32 | DN50 | DN50 | DN50 | DN50 |

Range | TPY32 | TPY45 | TPY64 | TYP90 | TPY120 | TPY150 | TPY200 |

Capacity(m3/h) | 32 | 45 | 64 | 90 | 120 | 150 | 200 |

Flow limitation(m3/h) | 16~40 | 25~55 | 30~80 | 50~120 | 60~150 | 80~180 | 100~240 |

Max pressure(bar) | 26 | 26 | 20 | 20 | 16 | 16 | 16 |

Motor power(kW) | 2.2~30 | 2.2~30 | 4~45 | 5.5~45 | 11-75 | 11-75 | 18.5-110 |

Maximum efficiency(%) | 76 | 78 | 76 | 75 | 74 | 73 | 79 |

Connections | |||||||

Flange | DN65 | DN80 | DN100 | DN100 | DN125 | DN125 | DN150 |

The picture of pump