Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

1W(Z) Series Marine (Self-priming) Vortex Pump

Date:2025-03-10Views:

1W(Z) Series Marine (Self-priming) Vortex Pump

Overview

1W(Z) Series marine self-priming vortex pumps are applicable for pumping potable water, washings and sanitary fresh water and sea water, as well as life pump and cooling pump(T<85℃).

Model Explanation 1W(Z) -3

1— Inlet and outlet diameters 1 inch

W(Z)—Marine vortex pump (Self-priming)

3—Integral number of specific speed divided by10

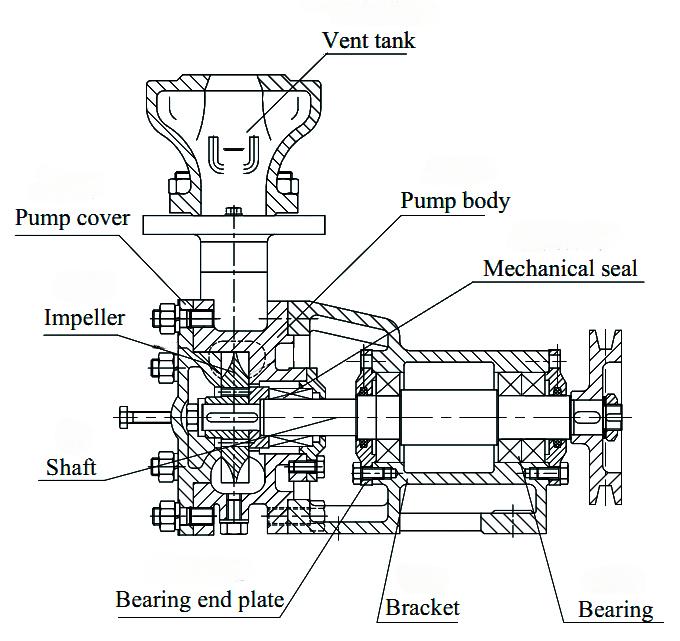

Structural Specifications

Performance Parameter

50HZ/2900RPM | 60HZ/3500RPM | 50HZ/60HZ | ||||||

Type | Capacity (m3/h) | Head (m) | Motor power (kW) | Capacity (m3/h) | Head (m) | Motor power (kW) | Weight (kg) | Hs (m) |

1W(Z)-3 | 6 | 40 | 1.5 | 7.2 | 57.6 | 2.2 | 28 | 4 |

1W-3 | 6 | 40 | 1.5 | 7.2 | 57.6 | 2.2 | 26 | 4 |

1W(Z)-0.9 | 3.6 | 102 | 3/4 | 4.32 | 146 | 5.5/7.5 | 26.5 | 4 |

1W-0.9 | 3.6 | 102 | 3/4 | 4.32 | 146 | 5.5/7.5 | 25.5 | 4 |

50HZ/1450RPM | 60HZ/1800RPM | 50HZ/60HZ | ||||||

Type | Capacity (m3/h) | Head (m) | Motor power (kW) | Capacity (m3/h) | Head (m) | Motor power (kW) | Weight (kg) | Hs (m) |

1W(Z)-3 | 3 | 10 | 0.75 | 3.6 | 14.4 | 1.1 | 28 | 4 |

1W-3 | 3 | 10 | 0.75 | 3.6 | 14.4 | 1.1 | 26 | 4 |

1W(Z)-0.9 | 1.8 | 25.5 | 1.1/1.5 | 2.2 | 36.7 | 1.5/2.2 | 26.5 | 4 |

1W-0.9 | 1.8 | 25.5 | 1.1/1.5 | 2.2 | 36.7 | 1.5/2.2 | 25.5 | 4 |

The picture of pump