Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Pump Parts

-

Marine Automatic Control Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Urban pump

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: material@hiseamarine.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

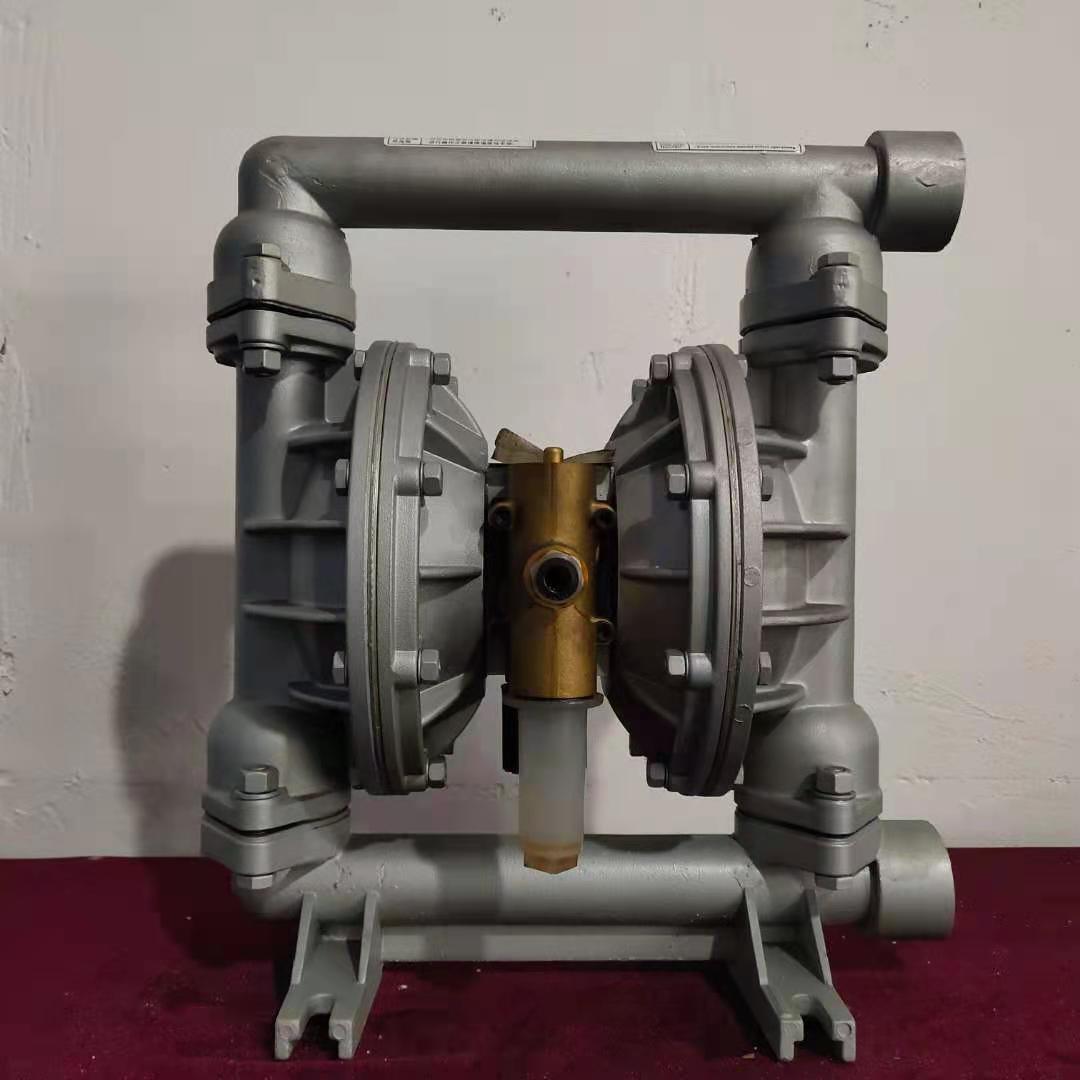

Marine Diaphragm Pump

Date:2025-03-10Views:

Marine Diaphragm Pump

Overview

Marine diaphragm pumps deliver leak-free, corrosion-resistant positive displacement for viscous, abrasive, and hazardous fluids. With ATEX Zone 1 compliance and pneumatic/hydraulic drive options, they excel in chemical cargo transfer, wastewater handling, and fuel additive injection systems, fully compliant with MARPOL Annex II and ISO standards.

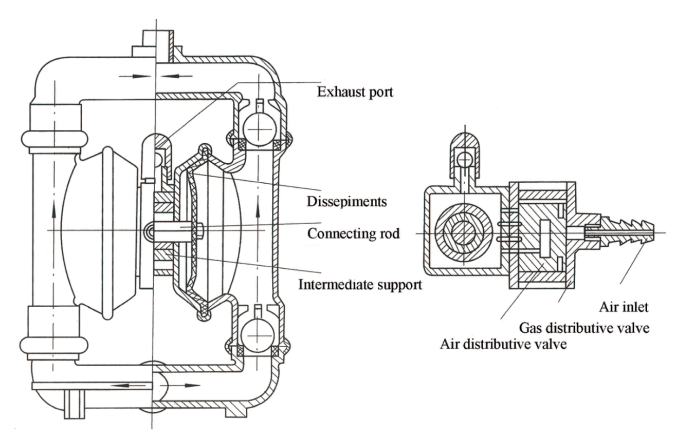

Working Principle

Reciprocating Diaphragm Action:Pneumatic/hydraulic actuator moves diaphragm to create volume displacement.

Suction Phase: Diaphragm retracts, creating vacuum to draw fluid.

Discharge Phase: Diaphragm extends, forcing fluid through check valves.

Zero Leakage: Diaphragm fully isolates fluid from drive components.

Applications

(1)Chemical Cargo Transfer

Media: H2SO4, NaOH, acetone

Capacity: 1-50m³/h @ ≤1.6MPa

(2)Oily Wastewater Transfer

Media: 20% solids bilge waste

Requirements: 6m self-priming

(3)Fuel Additive Dosing

Media: 10,000cP lubricity additives

Precision: ±2% metering accuracy

Certification

DNV/ABS/LR/CCS/BV.Etc.

Drawing