Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Cooling Water Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Hand Pump

-

Marine Pump Parts

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-13452620990

WhatsAPP/WeChat :+86-13452620990

Submersible Pump

Date:2025-04-14Views:

Sewage Submersible Pump

Introduce

With high-quality materials and components, the structural optimization of the pump by Fushi Pump engineers can save you 15% of energy costs and extend the continuous working time by more than 30% compared to ordinary manufacturers.

WQ-type sewage submersible pump adopts a unique single-channel impeller, and the dynamic seal adopts two sets of cemented carbide mechanical seals with special materials. The motor is separated by an oil chamber, which is non-clogging, high-efficiency, and energy-saving. Scope of application: The biggest advantage of this pump is that it can transport sewage containing solid particles and fibrous materials without clogging or entanglement. It is suitable for conveying industrial wastewater and urban domestic sewage. It can also be used as a drainage pump, a pulp pump, a filter flushing condensate circulating pump, and an irrigation pump and other sewage treatment occasions. It can also be used for pumping clean water.

The QW submersible type is especially suitable for occasions of frequent movement or temporary emergency use. It does not need to be fixedly installed. Just put on the rubber tube, connect the tube and put the pump into the bottom of the water to level it.

JYWQ (JPWQ) series automatic stirring sewage pump (sewage submersible pump) is suitable for conveying sewage or water containing solids and fibers.

ASWQ series tearing submersible sewage pump (sewage submersible pump) is developed with foreign advanced technology. It is suitable for supplying and discharging industrial and commercial sewage, domestic sewage, drainage system of urban sewage treatment plant, drainage station of civil air defense system, and water supply and drainage of waterworks. It is especially suitable for conveying liquids containing hard and fibrous substances, as well as particularly dirty, dry and slippery liquids.

Flow up to 4000m3/h

Head up to 800m

Features

1. The unique single-piece or double-piece impeller structure is adopted, which greatly improves the dirt passing capacity, and can effectively pass through fibrous substances with a diameter of 5 times the pump diameter and solid particles with a diameter of about 50% of the pump diameter.

2. The mechanical seal adopts a new type of hard and corrosion-resistant titanium tungsten material, which can make the pump run safely and continuously for more than 8,000 hours.

3. The overall structure is compact, the volume is small, the noise is low, the energy saving effect is remarkable, the maintenance is convenient, there is no need to build a pump room, and it can work by diving into the water, which greatly reduces the project cost.

4. There is a high-precision anti-interference water leakage detection sensor in the sealed oil chamber of the pump, and a thermal element is embedded in the stator winding to automatically protect the pump motor.

5. It can be equipped with a fully automatic control cabinet according to the needs of users, which can automatically protect the pump from water leakage, electric leakage, overload and over-temperature, etc., which improves the safety and reliability of the product.

6. The float switch can automatically control the start and stop of the pump according to the change of the required liquid level.

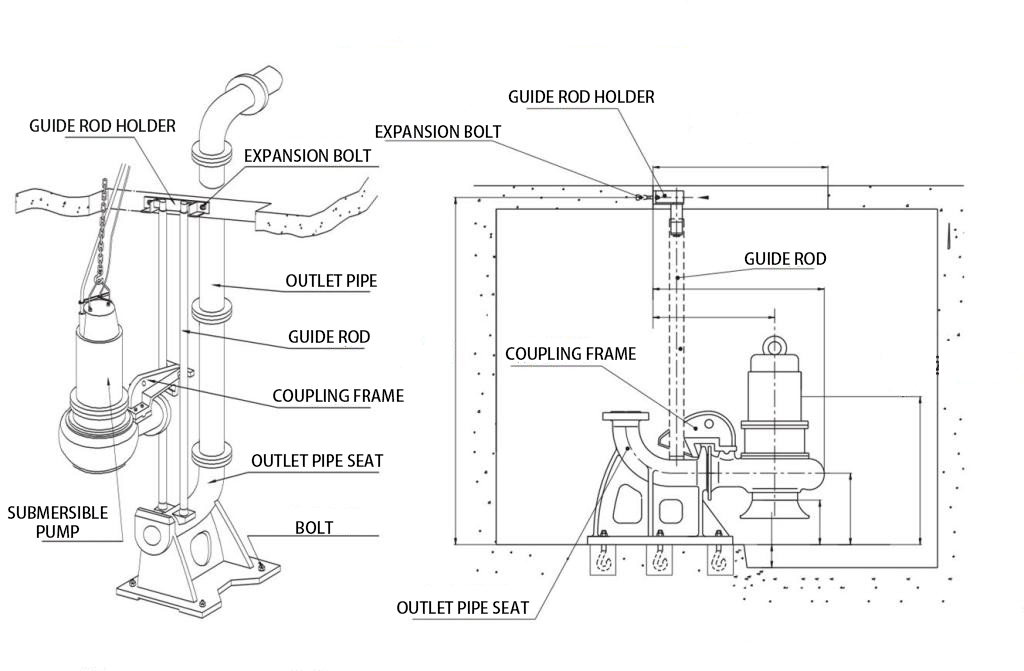

7. The WQ series can be equipped with a dual-rail automatic coupling installation system according to user needs, which brings greater convenience to installation and maintenance, and people do not need to enter the sump for this purpose.

8. It can be used in the full lift without overloading the motor.

9. There are two different installation methods, fixed automatic coupling installation system, free installation.