Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

Marine Cooling Water Pump

Date:2025-04-01Views:

Marine Cooling Water Pump

Overview

The marine cooling water pump is a critical component of a vessel’s power system, providing circulating cooling water for engines, generators, and auxiliary equipment to ensure optimal operating temperatures. Compliant with energy efficiency and environmental standards, it is suitable for bulk carriers, container ships, LNG carriers, and more, balancing reliability and energy savings.

Drive Options

Electric Drive: Powered by the ship’s main or emergency generator, offering stable and low-noise operation for routine cooling cycles.

Variable Frequency Drive (VFD) : Adjusts pump speed to match cooling load variations, saving up to 30% energy and reducing carbon emissions.

Applications

Engine Cooling: Supplies stable cooling water to main and auxiliary engines, preventing overheating.

Central Cooling System: Integrates with plate heat exchangers for closed seawater-freshwater loops, minimizing corrosion risks.

Seawater/Freshwater Circulation: Adapts to diverse water sources (seawater, freshwater, or mixed media) for complex operational needs.

Performance Parameters

Flow Range: 50 ~ 2000 m³/h.

Head Range: 20 ~ 80 m .

Operating Temperature: 5 ~ 95 °C.

Advantages

Corrosion Resistance & High Efficiency:Impeller and casing made of stainless steel 316L or bronze, resistant to seawater chloride corrosion and cavitation.

Optimized Hydraulic Design: Achieves IE4 energy efficiency, saving 25%~35% energy compared to conventional pumps.

Smart Monitoring & Protection:Equipped with temperature sensors and pressure transmitters for real-time data integration with central control systems.

Dry-Run Protection: Automatic shutdown prevents damage during dry operation.

Certifications & Compliance:Certified by DNV-GL, CCS, and ABS, meeting cooling requirements for Tier III emission-compliant vessels.

Low-Maintenance Design:Auto-Lubrication System,Extends bearing life to over 50,000 hours.

Modular Structure: Enables quick disassembly and reduces downtime.

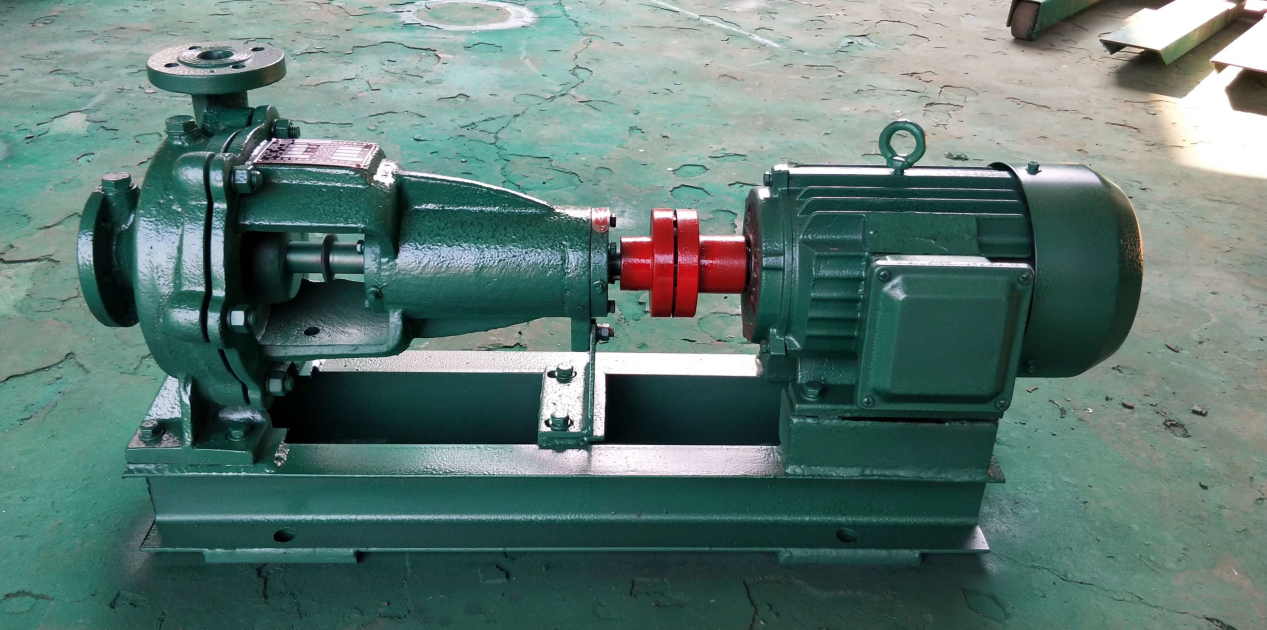

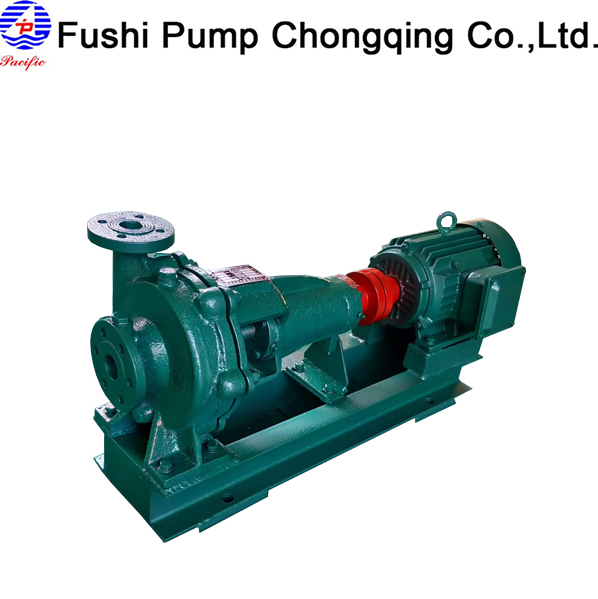

Product showcase:(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

| Marine Cooling Water Pump | ||||

|

|

|

| |

The picture of pump