Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Pump Parts

-

Marine Automatic Control Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Self-priming Pump

Chemical pump

Urban pump

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: sales@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-18983389474

CB Marine Bilge Pump

Date:2022-07-07Views:

Overview

CB marine bilge pump series, used for carrying water and physical and chemical properties similar to the use of liquid water, the liquid temperature not exceeding 85degrees C, applicable to ships pumping bilge, fire, health and other fresh water or sea water, as well as factories, mines, city and rural irrigation water supply use.

Advantages

1. It has strong reliability. Even if it is restarted after a long time of shutdown, it will not bite, and the restart can be carried out normally;

2. The efficiency is very high. In the process of use, there will be no too much noise. The installation form of fire pump is very flexible and convenient for maintenance, which can effectively save the cost of installation and maintenance. In addition, it can be made of different materials according to the user's purpose and under the condition of unchanged performance, which shall be put forward by the user when ordering.

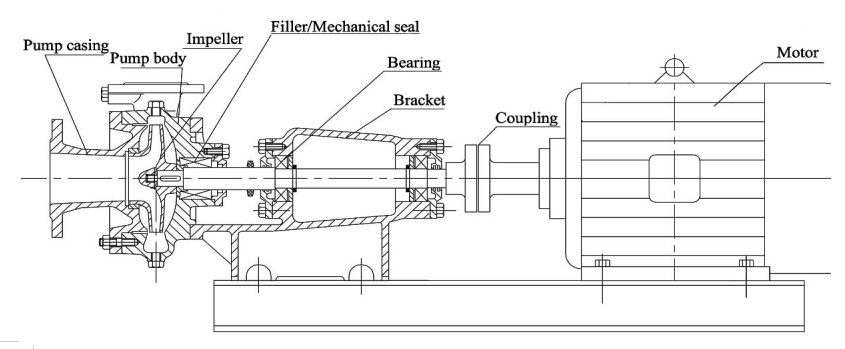

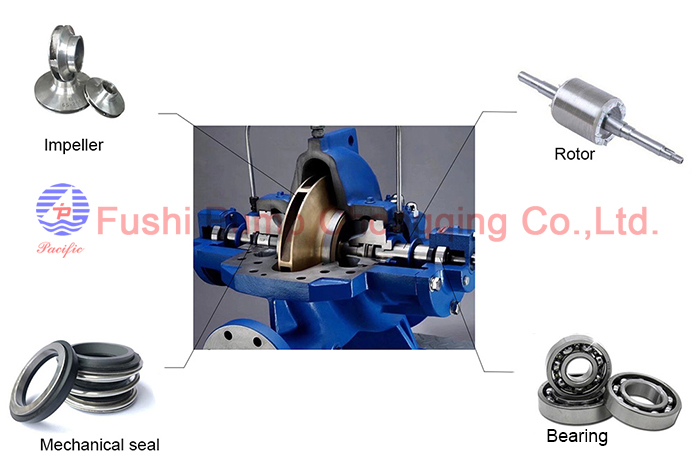

Drawing

The excellent design of our company's engineers, the components made of high-quality materials can make the pump have longer service time, lower maintenance frequency, and higher operating stability in complex environments, but it can also generate different prices.If you need more details about this, you can click on the news or send an email to ask us

Performance Parameter

(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

%20Service%20Marine.png)

Precautions for use

1. The maximum working pressure of the pump and the connected pipeline is ≤1.6MPa, and the pressure at the suction port of the pump + the pump head is ≤1.6Mpa. (If the working pressure of the pump system is greater than 1.6MPa, it should be put forward separately when ordering, so that we can use cast steel for the over-current parts and connecting parts of the pump during manufacture).

2. The ambient temperature does not exceed 50°C, the altitude does not exceed 1000 meters, and the relative humidity does not exceed 95%.

3. The conveying medium is clear water or other liquids with similar physical and chemical properties to clear water. (The conveying medium contains fine particles, which should be specified separately when ordering, so that we can assemble the wear-resistant mechanical seal.)

4. Before installing the pump, carefully check whether there are hard objects (such as stones, iron particles, etc.) in the pump flow channel that affect the operation of the pump, so as to avoid damage to the impeller and pump body when the pump is running.

5. The weight of the pipeline should not be added to the pump during installation, and there should be their own support bodies to avoid the deformation of the pump and affect the running performance and life.

6. The anchor bolts must be tightened during installation to avoid the impact of vibration on the pump performance during startup.

7. For the convenience of maintenance and safe use, a regulating valve is installed on the inlet and outlet pipelines of the pump and a pressure gauge is installed near the pump outlet to ensure the operation within the rated head and flow range, to ensure the normal operation of the pump and the growth of the pump. service life of the pump.

8. After installation, turn the pump shaft, the impeller should have no friction noise or stuck phenomenon, otherwise the pump should be disassembled to check the cause.