Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

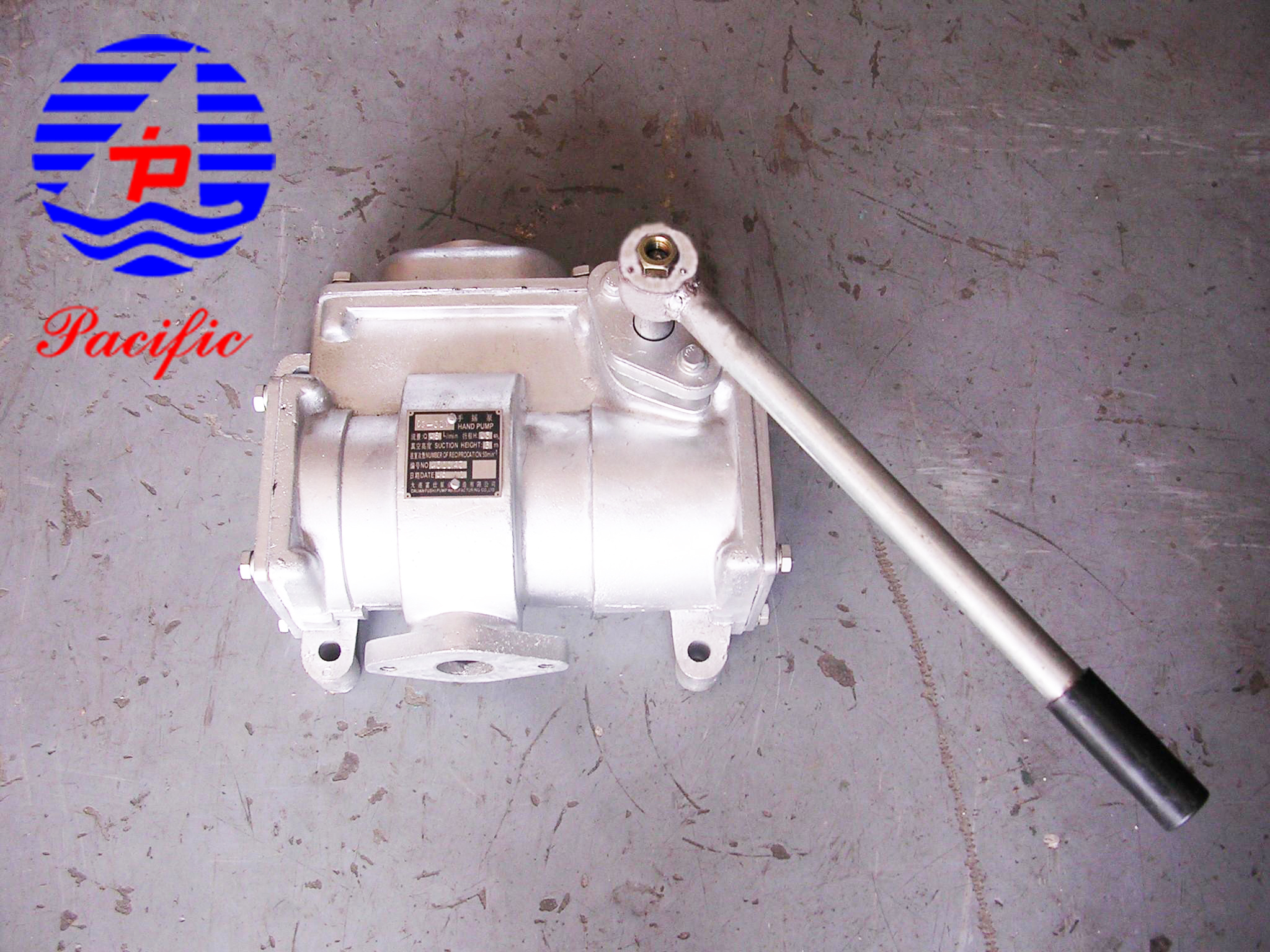

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

Marine Fuel Pump

Date:2025-04-01Views:

Marine Fuel Pump

Overview

The marine fuel oil pump is a critical component of a ship’s fuel system, responsible for the precise transfer, storage, and supply of fuel to main engines, auxiliary generators, and boilers. Compliant with pollution prevention and safety, it supports multiple fuel types, including diesel, heavy fuel oil (HFO), and marine gas oil (MGO), and is widely used on tankers, bulk carriers, and LNG-powered vessels.

Drive Options

Explosion-Proof Motor Drive: Meets ATEX/IECEx standards for safe operation in flammable environments.

Hydraulic Drive : Eliminates electrical dependency, ideal for extreme conditions or backup systems.

Applications

Fuel Bunkering & Transfer: Dock-to-ship or ship-to-ship (STS) fuel operations.

Main/Auxiliary Engine Supply: Delivers stable fuel pressure to diesel engines and generators.

Fuel Treatment Systems: Integrates with separators and filters for clean fuel delivery.

Boiler Fuel Supply: Ensures precise flow control for efficient steam system operation.

Performance Parameters

Flow Range: 10 ~ 2000 m³/h.

Head Range: 50 ~ 150 m .

Viscosity Range: 2 ~ 700 cSt .

Working Pressure: 0.5 ~ 4.0 MPa .

Advantages

Corrosion Resistance & Explosion Safety:Pump body and impeller made of stainless steel 316L or duplex steel 2205, resistant to high-sulfur fuel corrosion.

ATEX-Certified Motor: Ex d IIB T4 rating eliminates spark risks.

Smart Control & Energy Efficiency:VFD Speed Control: Dynamically adjusts flow to save up to 25% energy.

Pressure Feedback Loop: Stabilizes fuel pressure in real time.

Certifications & Compliance:Certified by DNV, CCS, and ABS.

Low Maintenance & Durability:Mechanical Seals: Leakage rate <0.01%, lifespan ≥20,000 hours.

Modular Design: Enables rapid replacement of wear parts, minimizing downtime.

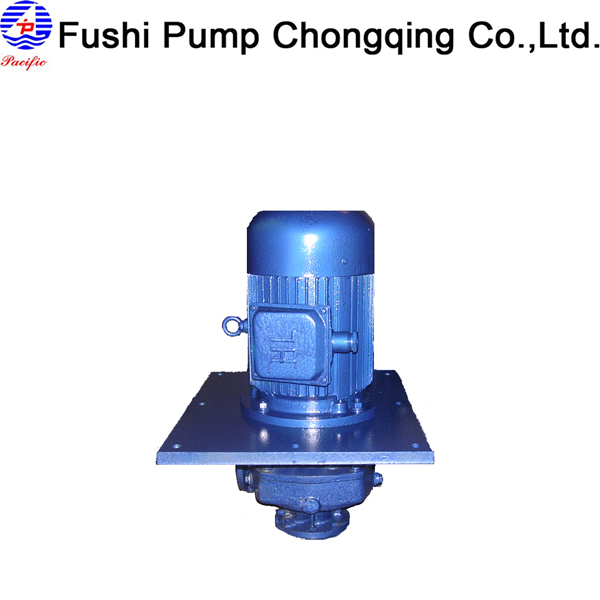

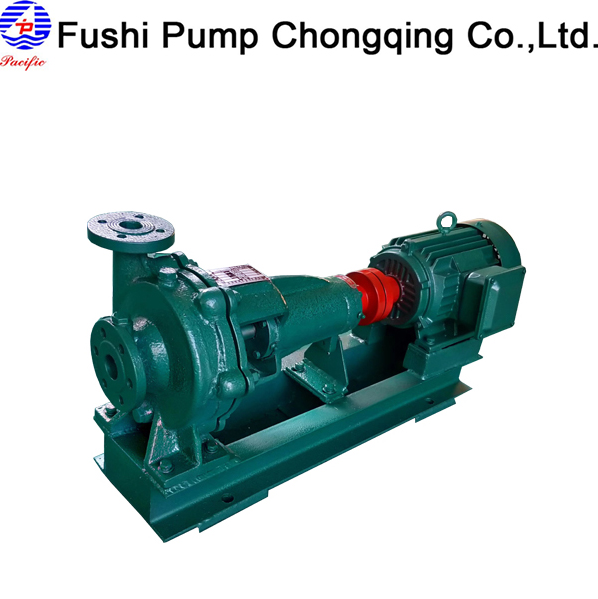

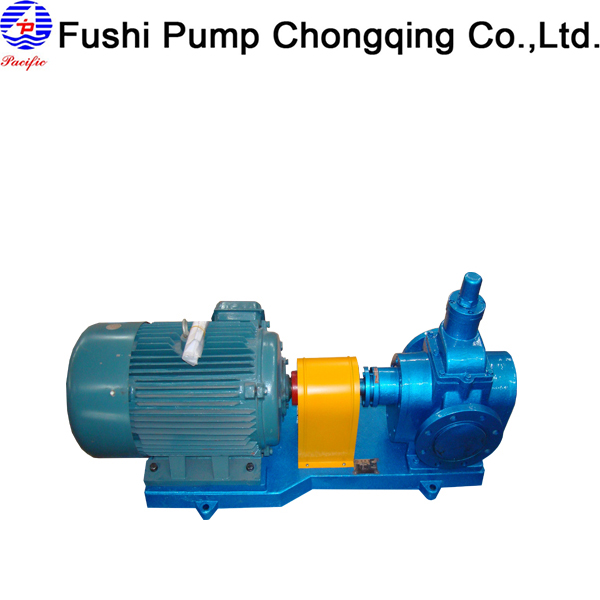

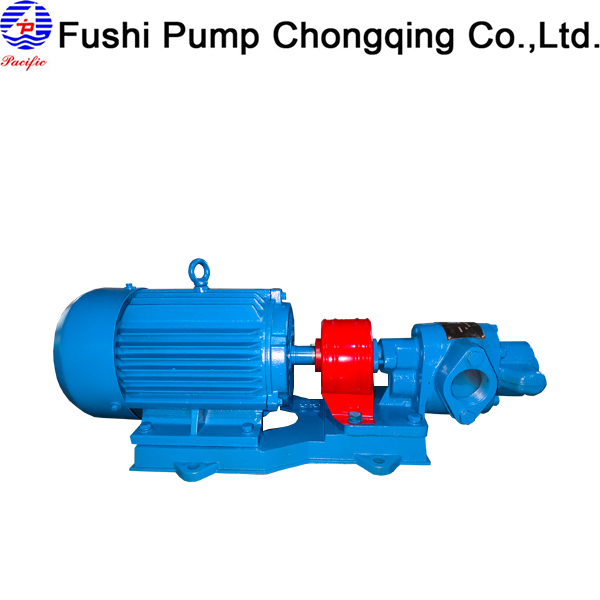

Product showcase:(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

| Marine Fuel Pump | ||||

|

|

|

| |

|

|

|

|

|

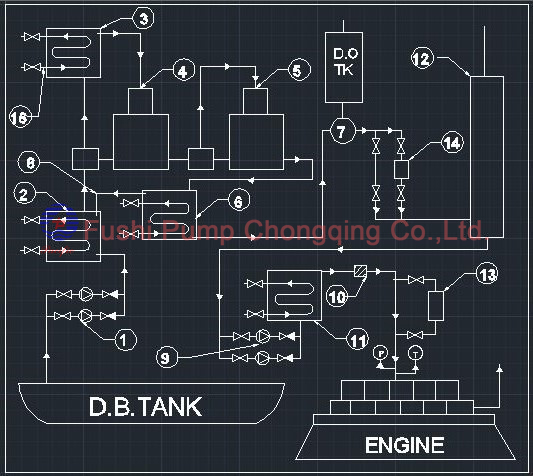

Detail of Fuel system

F. O. System. 1. Transfer Pump 2. Settling tank 3. Purifier Pre-heater 4. Purifier 1 5. Purifier 2 6. Service Tank 7. Change over Valve 8.Overflow line 9. Supply Pump 10. Fine Filter 11. Engine pre-heater 12. Mixing column 13. Viscometer 14. Flowmeter

Transfer Pump:- As the name suggests, this pump is used to transfer fuel oil. The fuel oil is transferred from the DB tank to the settling tank. When considering a pump, consider all of the following parameters to ensure safe and efficient operation of the pump (HFO is the fluidity that is heated to 30-35°C before passing through the pump).

Booster Pump:- This pump is used to pump the F.O from the mixing column to the engine preheater. Two pumps are used in the system, one is running and the other is on standby.

The pressure of the FO is also increased by this pump.

Picture of Marine Fuel Pump