Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Pump Parts

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-13452620990

WhatsAPP/WeChat :+86-13452620990

Marine Lubricating Oil Pump

Date:2025-04-01Views:

Marine Lubricating Oil Pump

Overview

The marine lubricating oil pump serves as a critical component of vessel propulsion systems, engineered for precision delivery of high-temperature lubricants to main engines, gearboxes, and bearings. Its robust construction ensures stable oil pressure and metered flow rates, significantly reducing mechanical wear while extending equipment service life. Compliant with ISO cleanliness standards and DNV-GL endurance certification, this pump is widely deployed across bulk carriers, container ships, and offshore support vessels.

Drive Options

Electric Drive: Integrated with intelligent frequency control to auto-adjust oil pressure based on load demands, achieving up to 25% energy savings.

Mechanical Drive (Optional): Direct coupling to main engine shafts eliminates auxiliary power consumption, ideal for redundant lubrication systems.

Applications

Main Engine Lubrication: Continuous oil film supply for low-speed two-stroke diesel engines.

Gearbox Circulation: Cooling and lubricating reduction gear assemblies to prevent micropitting.

Hydraulic System Supply: Maintaining stable pressure for deck machinery (cranes, windlasses).

Performance Parameters

Flow Range: 10 ~ 200 L/min.

Operating Pressure: 0.5 ~ 4.0 MPa .

Media Temperature: -20°C ~ 150°C .

Advantages

High-Temperature & Wear Resistance:Nitrided steel gears and ceramic-coated surfaces withstand 150°C operations and extreme pressure.

Sealing System: Mechanical seal leakage rate <0.01mL/h.

Smart Pressure Management:

Certifications & Compliance:Certified by ABS, LR for low-sulfur fuel compatibility.

Energy Efficiency:Helical involute gear design achieves >95% volumetric efficiency with 18% reduced energy consumption.

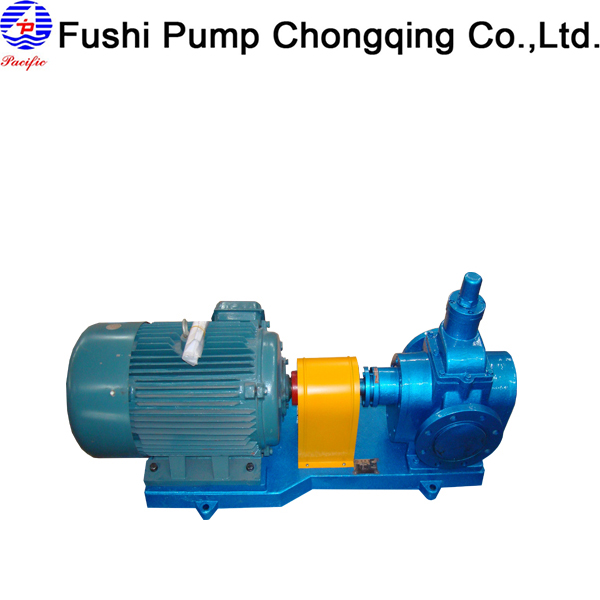

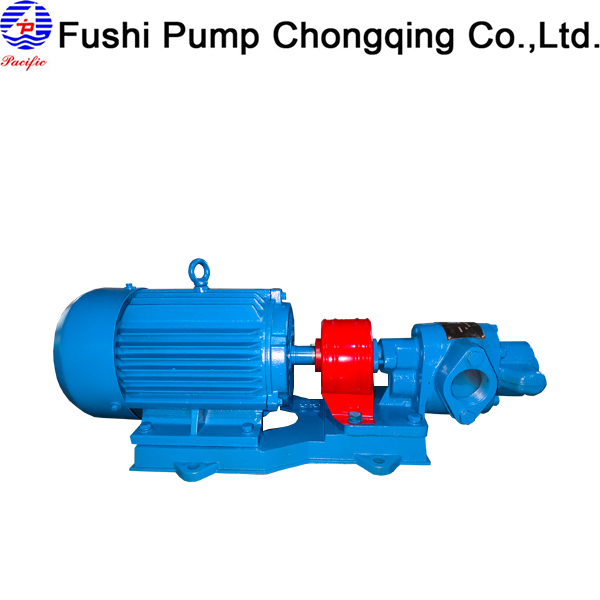

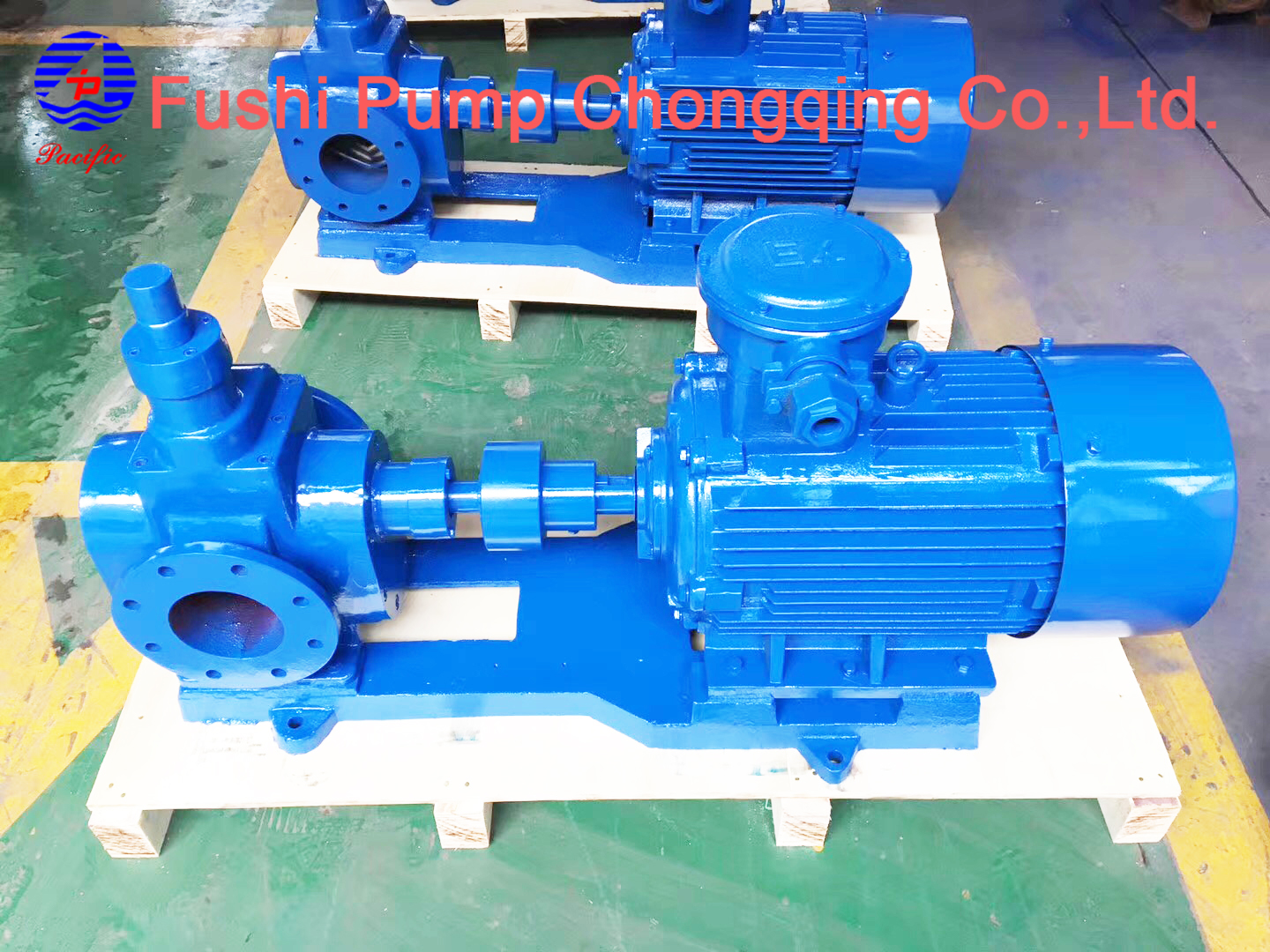

Product showcase:(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

| Marine Lubricating Oil Pump | |||

|

|

| |

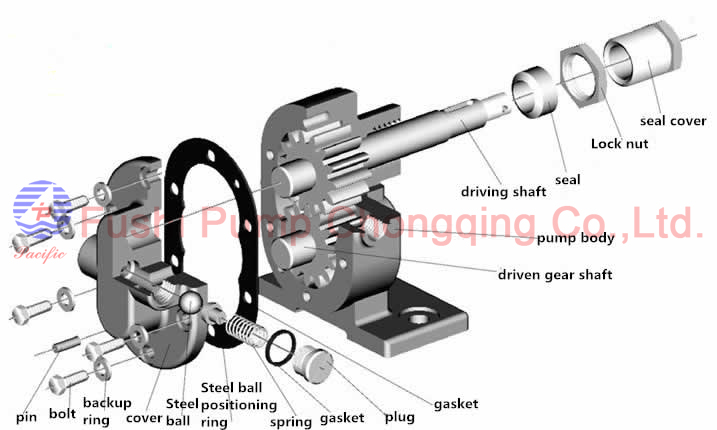

Working Principle of Marine Oil Pump

When the meshing gear rotates in the main body of the pump, the gear goes in and out of meshing continuously.In the suction chamber, the teeth of the gear gradually break away from the meshing state, the volume of the suction chamber gradually increases, the pressure decreases, and enters the suction chamber under the action of liquid surface pressure, and enters the discharge chamber with the gear teeth. In the discharge chamber, the teeth of the gear gradually become meshing again, the teeth of the gear are gradually occupied by the teeth of the gear, the volume of the discharge chamber is reduced, and the hydraulic pressure of the discharge chamber increases, so the liquid is discharged from the pump outlet. The gear continues to rotate, and the above process continues to form a continuous oil supply process.

Picture of Marine Lubricating Oil Pump

.jpg)