Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

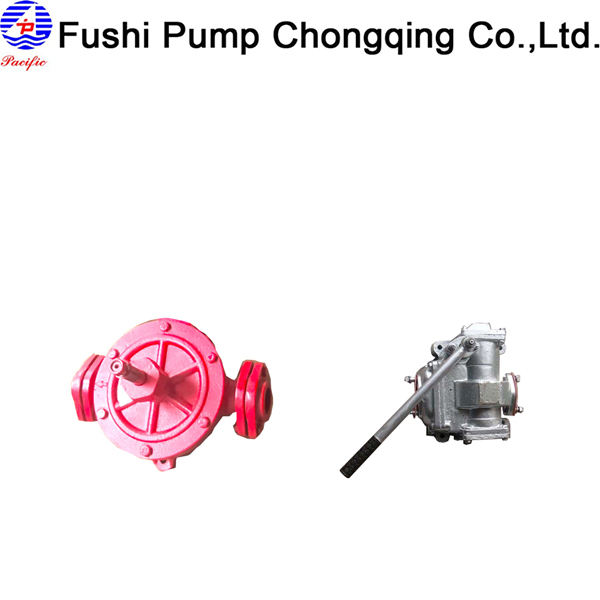

Marine Hand Pump

-

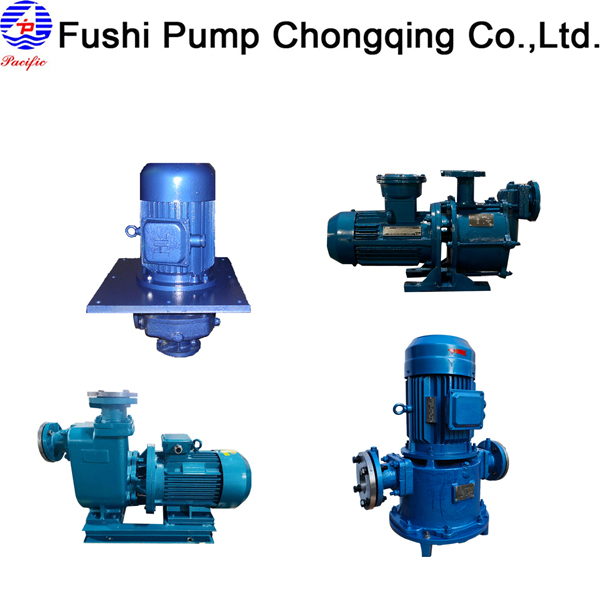

Marine Centrifugal Pump

-

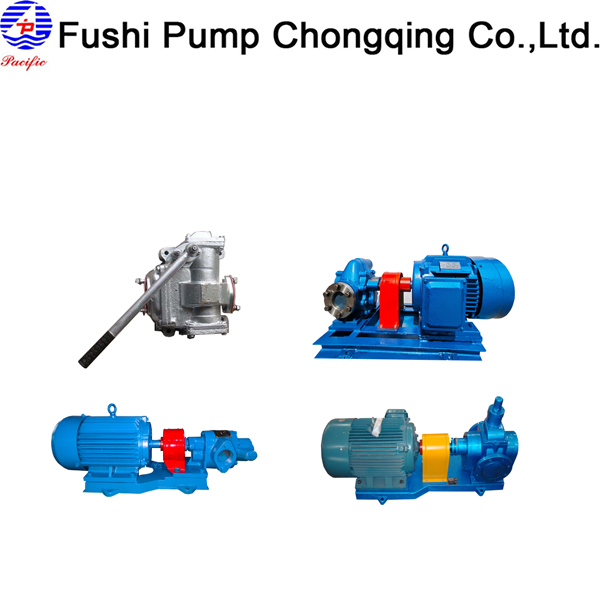

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

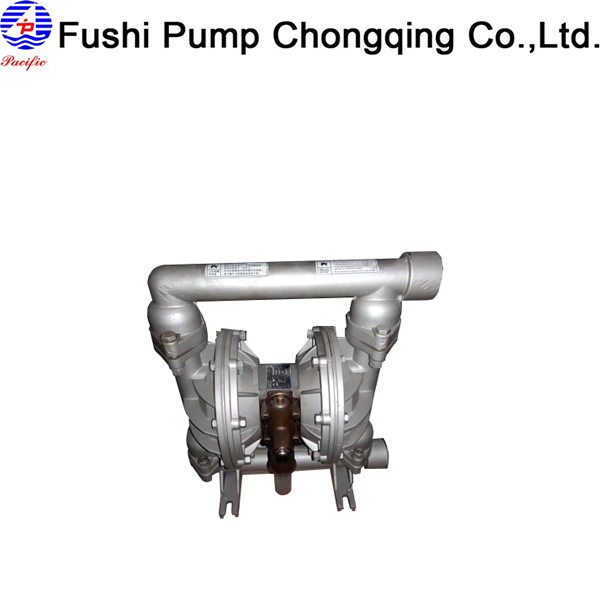

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

Marine Pump

Date:2025-04-01Views:

Marine Pump

Overview

Marine pumps serve as the core equipment in marine engineering, tasked with fluid transportation, pressure regulation, and system function realization. Their designs integrate fluid mechanics, materials science, and intelligent control technology, adhering strictly to international standards such as IMO, DNV, and ABS. Widely applied in merchant ships, special vessels, and offshore engineering, marine pumps act as the "power heart" ensuring safe and efficient maritime operations.

Materials

(1)Cast Iron (HT200)

Applications: Centrifugal pump casings, non-wetted structural components

Advantages:200 MPa compressive strength, superior wear resistance to cast steel,1/3 the cost of stainless steel, suitable for mass production

Limitations:Max temperature 250℃, pressure capacity <1.6 MPa,Requires epoxy coating to prevent seawater corrosion\

(2) Cast Steel (ZG200-400)

Applications: High-pressure piston pump valves, gear pump housings

Technical Features:200 MPa yield strength, pressure tolerance up to 5 Mpa,Chrome-plated surface for acid/alkali resistance (pH 2-12)

Manufacturing Process:Investment casting with CT6 dimensional accuracy,Heat-treated to HRC 20-25 hardness

(3) Copper(ZCuZn16Si4)

Media Compatibility: Freshwater systems, hydraulic fluids

Performance Highlights:385 W/(m·K) thermal conductivity for efficient heat dissipation,Self-lubricating properties ideal for high-speed rotors (e.g., screw pump shafts)

Engineering Case: Silicon-bronze impellers in a luxury cruise ship’s freshwater system extended service life to 8,000 hours

(4)Stainless Steel (304/316L)

Core Advantages:316L with 2.5% molybdenum resists chloride corrosion (>100,000 ppm)

Special Treatments:Surface polished to Ra 0.8μm to minimize media retention,TIG welding prevents intergranular corrosion

Classification

By Working Principle:Hand Pump Centrifugal Pump Screw Pump Gear Pump Vortex Pump Ejector Pump Diaphragm Pump Piston Pump

By Application:Fire Pump Emergency Fire Pump Ballast Water Pump Fuel Pump Lubricating Oil Pump Bilge Pump Sewage Pumps Fresh Water Pump General Pump Cargo Oil Pump Cooling Water Pump

Quality Certification System

Our company operates under a mature quality assurance system with strict quality control processes. Products are certified to:

ISO 9001 Quality Management System

CCS (China Classification Society)

Optional certifications available upon request:

Chinese military inspection

Chinese fisheries inspection

LR , ABS ,GL , KR, NK, DNV , BV

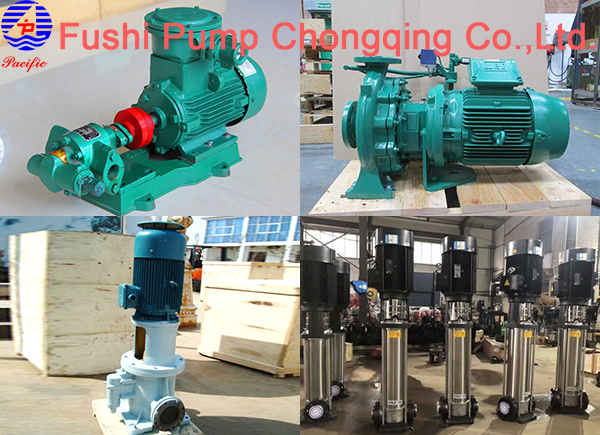

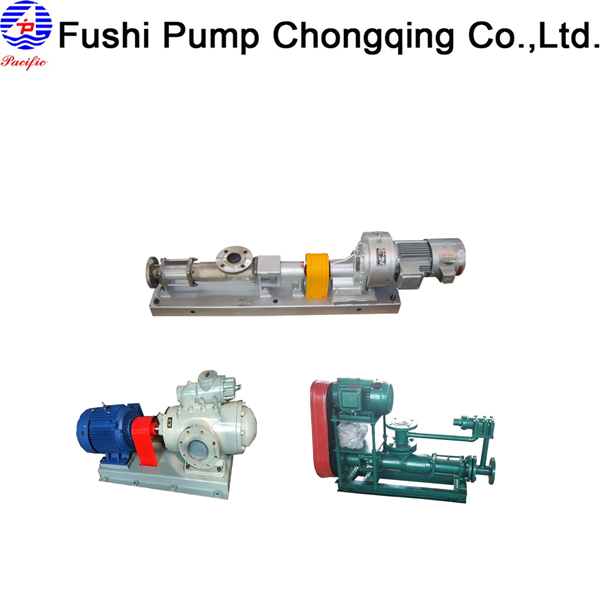

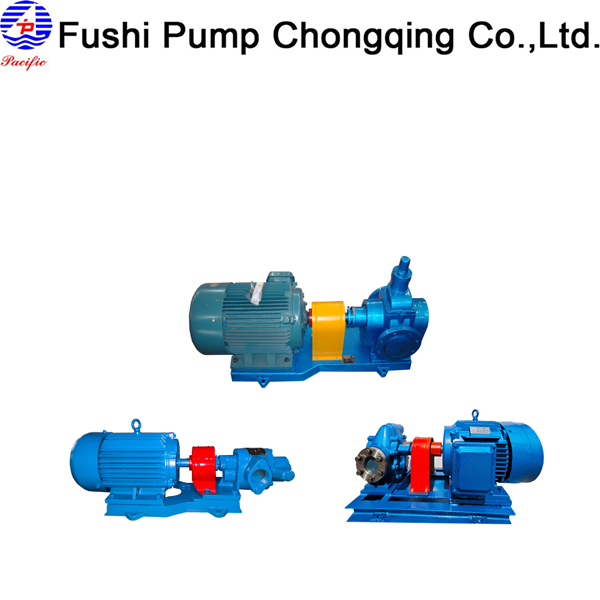

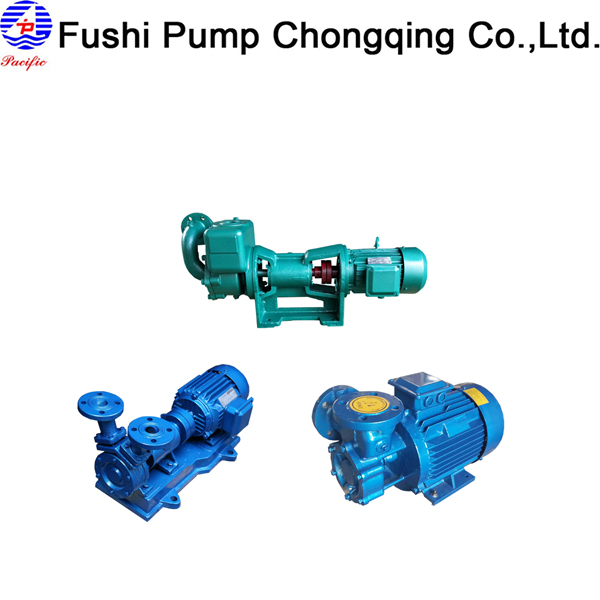

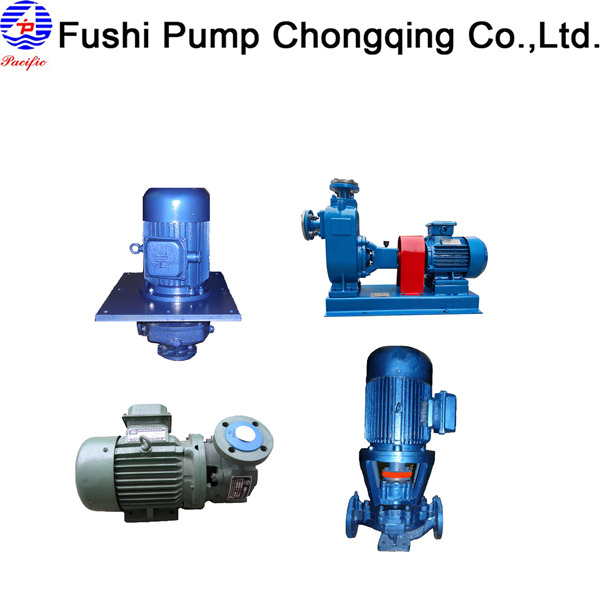

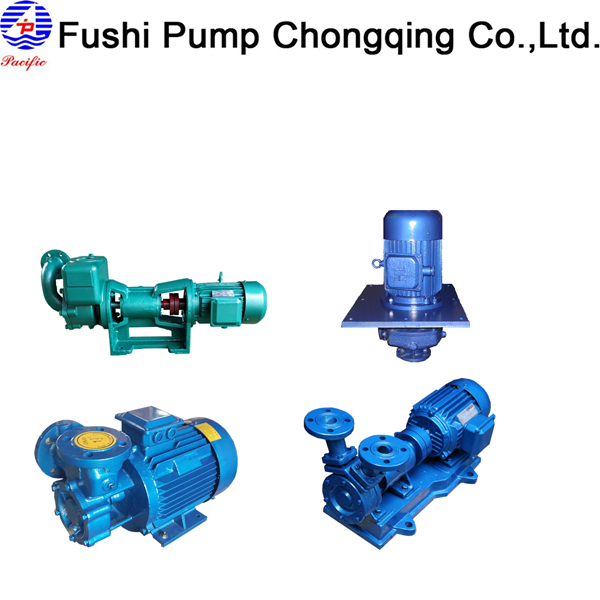

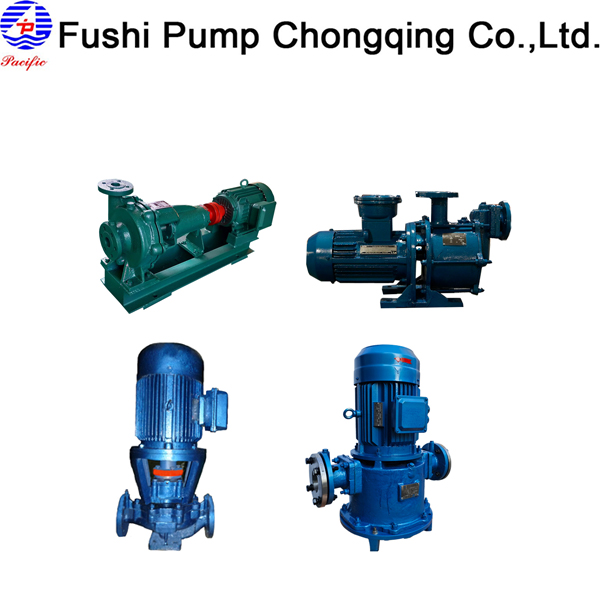

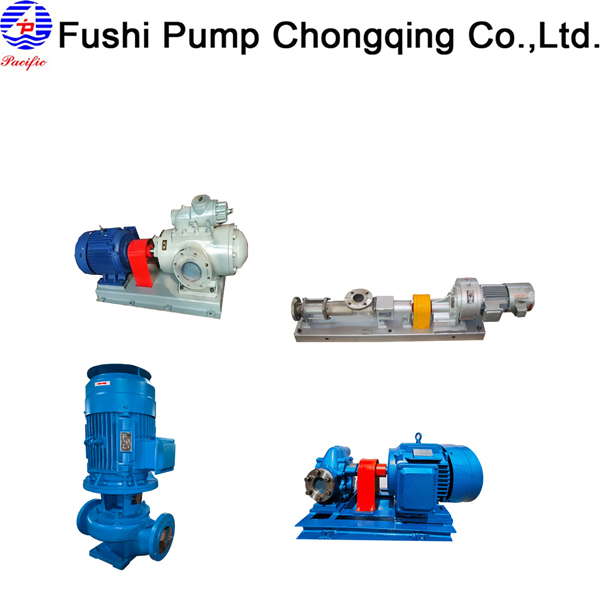

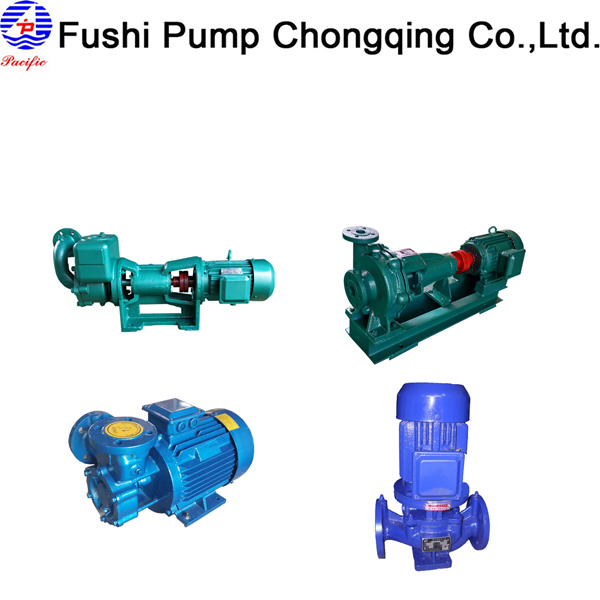

Product showcase:(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

| Working Principle | |||

|

|

|

|

|

|

| |

| Application | |||

|

|

|

|

|

|

| |

|

| ||

Working Principle of Marine Oil Pump