Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Pump Parts

-

Marine Automatic Control Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Self-priming Pump

Chemical pump

Urban pump

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: sales@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-18983389474

BL Marine Horizontal Direct-coupled Centrifugal Fire Pump

Date:2023-02-16Views:

BL Marine Horizontal Direct-coupled Centrifugal Domestic Pump

Overview

Fire pumps play a crucial role in ensuring the safety of buildings and people in the event of a fire. They are responsible for delivering water to the sprinkler system or other fire suppression systems. One of the popular types of fire pumps is the horizontal direct-coupled centrifugal fire pump. The BL Marine Horizontal Direct-Coupled Centrifugal Fire Pump is designed for use in marine applications, such as ships and offshore platforms.

The pump is engineered to meet the strict requirements of marine regulations and standards. The pump is suitable for seawater, fresh water, and other non-corrosive liquids. It is a compact and lightweight fire pump that delivers high flow rates and pressures.

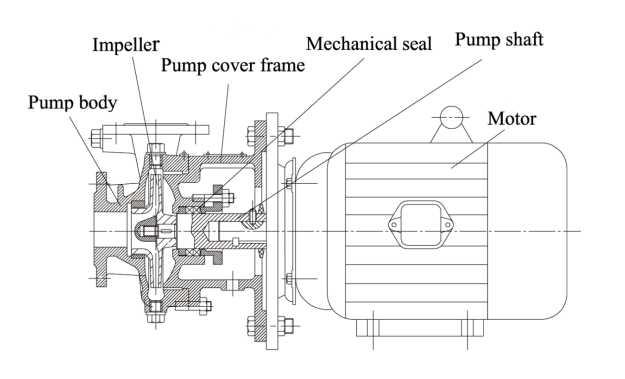

This type of pump is BA type pump based on the improvement of the structure, has the advantages of small, light weight, simple structure and convenient handling characteristics. The performance parameters of BA pump with the same. Liquid temperature not exceeding 100℃, with mechanical seal. produced BL type marine centrifugal pump impeller with silicon brass, a pump shaft is made of stainless steel.

Key Features of BL Marine Horizontal Direct-Coupled Centrifugal Fire Pump

The BL Marine Horizontal Direct-Coupled Centrifugal Fire Pump comes with a range of features that make it a reliable and efficient fire pump. These features include:

Direct-coupled design: The pump is designed with a direct-coupled motor that eliminates the need for a separate coupling or alignment. This design reduces the overall size and weight of the pump, making it easier to install and maintain.

High flow rates and pressures: The BL Marine Horizontal Direct-Coupled Centrifugal Fire Pump can deliver high flow rates and pressures up to 1750 GPM and 16 bar respectively. These flow rates and pressures make it suitable for use in large marine vessels and offshore platforms.

Compact and lightweight: The pump has a compact and lightweight design that makes it suitable for use in limited spaces. It is also easy to transport and install, making it a popular choice for marine applications.

Corrosion-resistant construction: The pump is made from high-quality materials that are resistant to corrosion and wear. This construction ensures that the pump can withstand harsh marine environments and last for a long time.

Low noise levels: The pump is designed to operate quietly, which is essential in marine applications where noise levels need to be kept to a minimum.

Model Explanation 2BL -6A

2—Inlet diameter 2 inch

BL—Marine horizontal direct-coupled centrifugal pump

6—Specific speed divided by10

A(B)—Impeller processed with 1(2)time cutting

Structural Specifications

The excellent design of our company's engineers, components made of high-quality materials can extend the life of the pump, reduce the frequency of maintenance, operation stability in complex environments, but it also cause different prices. If you need more details about this, you can click on the news or send an email to ask us

Performance Parameter

(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

BL Marine Horizontal Direct-Coupled Centrifugal Fire Pump is a reliable and efficient fire pump that is designed for use in marine applications. Its direct-coupled design, high flow rates and pressures, compact and lightweight construction, corrosion-resistant materials, and low noise levels make it a popular choice for marine vessels and offshore platforms. The pump is easy to install and maintain, and its high reliability ensures that it can operate for long periods without any issues. Its suitability for a range of marine applications makes it a versatile and essential component for ensuring the safety of people and equipment in the event of a fire.

Product Notes and Maintenance

1. After starting the pump, check whether the running current of the motor and the operation of the water pump are normal. If there is any abnormality, stop the pump immediately.

2. Check the pressure gauge at the outlet of the water pump. When the pointer of the pressure gauge reaches the rated working pressure and is stable, gradually open the outlet valve to make the pump work under the rated state as far as possible.

3. After the pump is filled with water normally, move the clutch handle installed for vacuum suction to the "off" position.

4. Check the pressure of the valve group. The pressure of the clean water valve group is about 0.8MPa, and that of the foam valve group is about 1.0MPa. If the pressure cannot be maintained, the pump outlet and return valve can be properly adjusted to control the pressure.

5. The temperature of the pump and motor bearing shall be checked frequently, the maximum temperature shall not exceed 75 ℃, and the working current of the motor shall be within the normal range.

6. After stopping the pump, restore all valves to the normal state according to the requirements of the valve opening and closing state diagram.