Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

QBY Marine Air Operated Pneumatic Diaphragm Bilge Pump

Date:2025-03-06Views:

QBY Marine Air Operated Pneumatic Diaphragm Bilge Pump

Overview

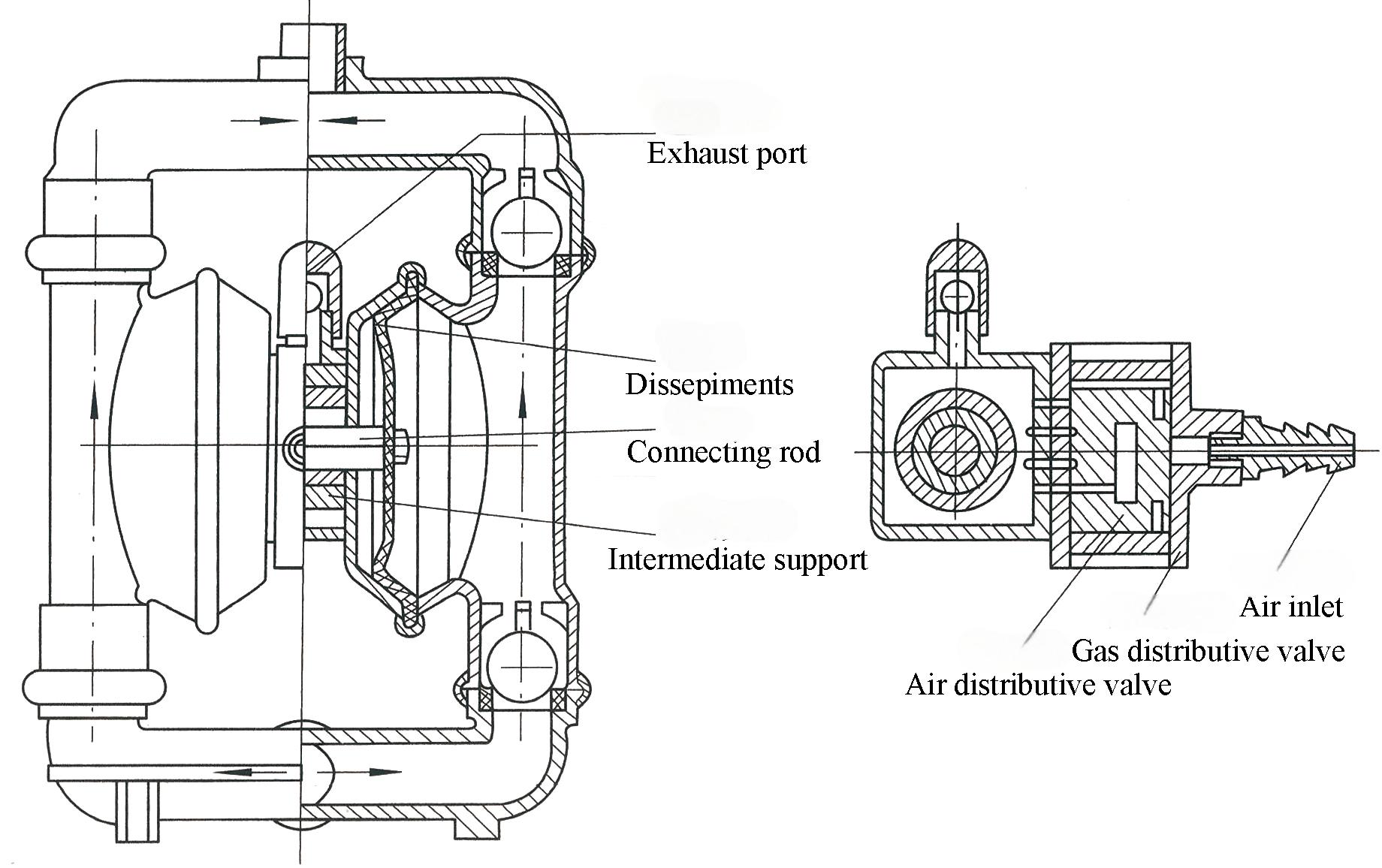

QBY air operated pneumatic diaphragm pumps not only can exhaust the flow liquid, but also can convey some uneasy flowed medium, with the merits of self-pumping pump, diving pump, shield pump and impurity pump etc. It’s unnecessary to pour the drawing water; wide flow and good performance. The diameter allowed to pass the Max grain reaches 10mm. the damage is very less to the pump while exhausting the slurry and impurity. The delivery Head and flow can pass the pneumatic valve open to realize the stepless adjustment; this pump has no rotary parts and no bearing seals. The diaphragm will completely separate the exhausted medium and pump running parts, working medium. The conveyed medium can’t be leaked outside. Thus is will not cause the environmental pollution and human body safety dangerous while exhausting the toxin and flammable or corrosive medium; no electricity, it’s safe and reliable while using in the flammable and explore places; it can be soaked in medium; it’s convenient to use and reliable to work. Only open or close the gas valve body while starting or stopping. Even if no medium operation or pausing suddenly for long time because of accident matters, the pump will not be damaged caused by this. Once over-loading, the pump will automatically stop and possesses the self protection function. When the load recovers normally, it also can start automatically; simple structure and less wearing parts. This pump is simple in structure, installation and maintenance. The medium conveyed by the pump will not touch the matched pneumatic valve and coupling lever etc. not like other kinds pumps, the performance will drop down gradually because of the damages of rotor, gear and vane etc; it can transmit the adhesive liquid (the viscosity I below 1000centipoise); this pump needn’t the oil lubricant. Even if idling, it has and influence to the pump. This is a characteristic of this pump.

Structural Specifications

Performance Parameter

Type | Capacity (m3/h) | Head (m) | Exit pressure (kgf/cm2) | Sucked (m) | Max grain Dia. (mm) | Max peressure (kgf/cm2) | Max air consumption (m3/min) |

QBY-10 | 0-0.8 | 0-50 | 6 | 5 | 1 | 7 | 0.3 |

QBY-15 | 0-1 | 0-50 | 6 | 5 | 1 | 7 | 0.3 |

QBY-25 | 0-2.4 | 0-50 | 6 | 7 | 2.5 | 7 | 0.6 |

QBY-40 | 0-8 | 0-50 | 6 | 7 | 4.5 | 7 | 0.6 |

QBY-50 | 0-12 | 0-50 | 6 | 7 | 8 | 7 | 0.9 |

QBY-65 | 0-16 | 0-50 | 6 | 7 | 8 | 7 | 0.9 |

QBY-80 | 0-24 | 0-50 | 6 | 7 | 10 | 7 | 1.5 |

QBY-100 | 0-30 | 0-50 | 6 | 7 | 10 | 7 | 1.5 |

The picture of pump