Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

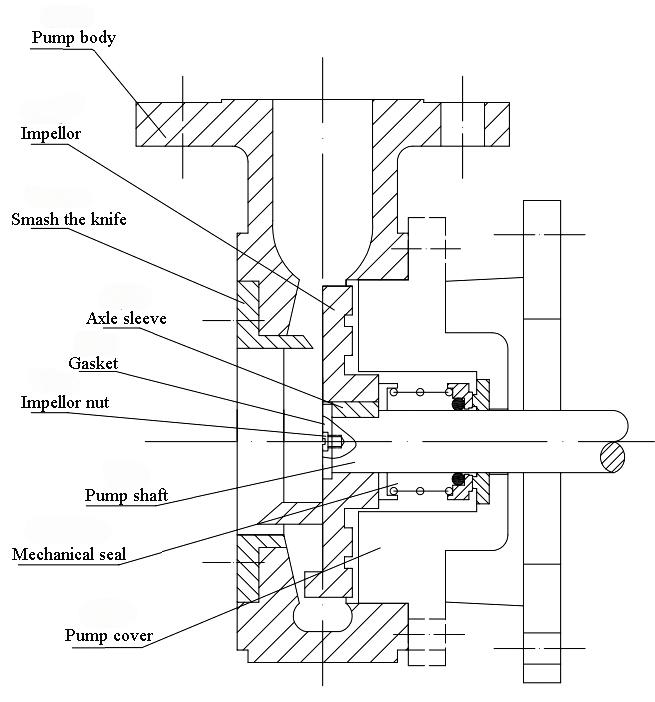

C(P)WF Marine Crushing Sewage Pump

Date:2025-03-07Views:

C(P)WF Marine Crushing Sewage Pump

Overview

C(P) WF Series marine (life) is suitable for crushing pump, drainage dirt grinding and pumping, such as paper, food residue, sludge, sludge dry stool, the largest circulation after crushing solid particle diameter less than5mm, easy jet, is more suitable for low temperature condensation smash.

Model Explanation 3C(P)WF-10(B)

3—Rated discharge 30m3/h

C (P)—Marine

W—Drainage contamination

F—Crushing model

10—Rated dis head 0.1MPa

B—Improved Impeller

Structural Specifications

Performance Parameter

C(P)WF | 50HZ/2900RPM | 60HZ/3500RPM | 50HZ/60HZ | |||||

Type | Discharge (m3/h) | Dishead (Mpa) | Power (kW) | Weight (kg) | Discharge (m3/h) | Dishead (Mpa) | Power (kW) | Inlet/out dia. (mm) |

3C(P)WF-30(B) | 30 | 0.30 | 7.5 | 85 | 36 | 0.43 | 11 | 80/50 |

3C(P)WF-25(B) | 30 | 0.25 | 5.5 | 75 | 36 | 0.36 | 11 | 80/50 |

3C(P)WF-10(B) | 30 | 0.10 | 4.0 | 42 | 36 | 0.14 | 7.5 | 80/50 |

2.5C(P)WF-20(B) | 25 | 0.20 | 4.0 | 37 | 30 | 0.29 | 7.5 | 65/40 |

2.5C(P)WF-10 (B) | 25 | 0.10 | 3.0 | 32 | 30 | 0.14 | 5.5 | 65/40 |

2.5C(P)WF-5(B) | 25 | 0.05 | 2.2 | 26 | 30 | 0.07 | 4.0 | 65/40 |

2C(P)WF-11(B) | 20 | 0.11 | 2.2 | 26.4 | 24 | 0.16 | 4.0 | 65/32 |

1C(P)WF-11B) | 10 | 0.11 | 1.5 | 26 | 12 | 0.16 | 3.0 | 65/32 |

0.5C(P)WF-10~15(B) | 5 | 0.10~0.15 | 1.1 | 24 | 6 | 0.14~0.22 | 2..2 | 50/32 |

0.5C(P)WF-8 | 5 | 0.08 | 0.75 | 20 | 6 | 0.12 | 1.5 | 50/32 |

The picture of pump