Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

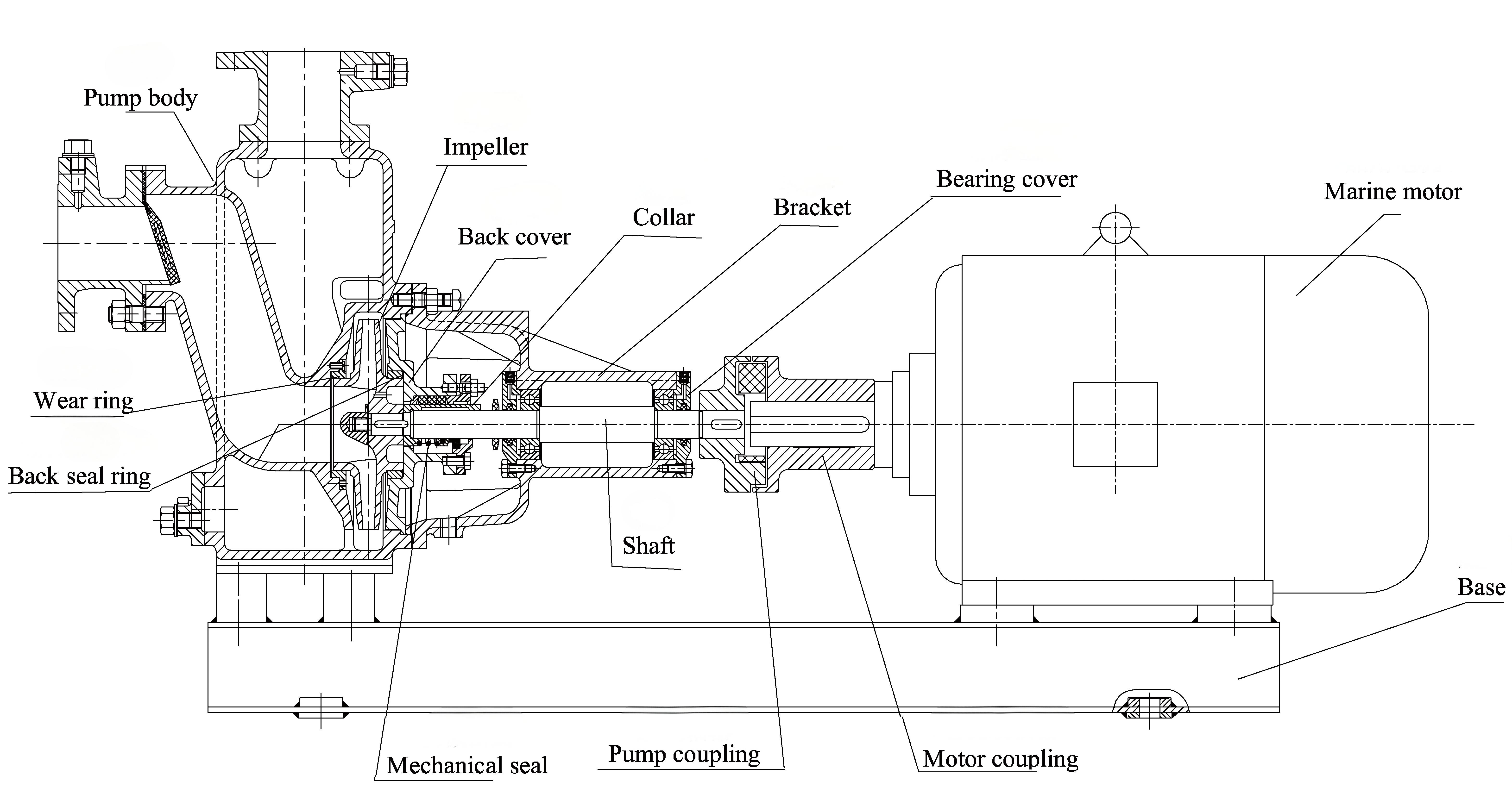

CWZ Marine Horizontal Self-priming Centrifugal Cargo Oil Pump

Date:2025-03-07Views:

CWZ Marine Horizontal Self-priming Centrifugal Cargo Oil Pump

Overview

CWZ Series marine Horizontal self-priming centrifugal pump has the advantages of compact structure, beautiful appearance, good self-priming performance. According to different media, using different materials, applicable to transport ship bilge and ballast water or for cooling sea water, fire, sanitation, transportation temperature is not higher than 85 ℃seawater or freshwater.

Model Explanation 3CWZ-5

32—Inlet and outlet diameter 32 mm

CWZ—Marine Horizontal self-priming centrifugal pumps

5—Impeller specific speed divided by 10 compared with the integer value addition.

Structural Specificati

Performance Parameter

CWZ | 50HZ | 60HZ | 50HZ/60HZ | ||||||

Type | Capacity (m3/h) | Head (m) | Power/Motor (kW) | Capacity (m3/h) | Head (m) | Power/Motor (kW) | Efficiency (%) | (NPSH)r (m) | Weight (kg) |

32CWZ-5 | 8 | 21 | 1.5/Y90S-2H | 9.6 | 30.2 | 3/Y100L-2H | 38 | 4 | 28 |

32CWZ-4 | 8 | 30 | 2.2/Y90L-2H | 9.6 | 43.2 | 4/Y112M-2H | 40 | 4 | 29 |

32CWZ-3 | 8 | 42 | 4/Y112M-2H | 9.6 | 60.5 | 5.5/Y132S1-2H | 36 | 4 | 30 |

40CWZ-6 | 12 | 21 | 2.2/Y90L-2H | 14.4 | 30.2 | 3/Y100L-2H | 52 | 4 | 42 |

40CWZ-5 | 12 | 30 | 3/Y100L-2H | 14.4 | 43.2 | 4/Y112M-2H | 51 | 4 | 50 |

40CWZ-4 | 12 | 42 | 4/Y112M-2H | 14.4 | 60.5 | 5.5/Y132S1-2H | 47 | 4 | 50 |

50CWZ-8 | 21 | 21 | 3/Y100L-2H | 25.2 | 30.2 | 5.5/Y132S1-2H | 51 | 4 | 46 |

50CWZ-6 | 21 | 30 | 4/Y112M-2H | 25.2 | 43.2 | 7.5/Y132S2-2H | 56 | 4 | 60 |

50CWZ-5 | 21 | 42 | 5.5/Y132S1-2H | 25.2 | 60.5 | 11/Y160M1-2H | 52 | 4 | 52 |

65CWZ-11 | 36 | 21 | 4/Y112M-2H | 43.2 | 30.2 | 7.5/Y132S2-2H | 64 | 4 | 50 |

65CWZ-8 | 36 | 30 | 5.5/Y132S1-2H | 43.2 | 43.2 | 11/Y160M1-2H | 61 | 4 | 52 |

65CWZ-6 | 36 | 42 | 11/Y160M1-2H | 43.2 | 60.5 | 15/Y160M2-2H | 57 | 5 | 65 |

65CWZ-5 | 36 | 60 | 15/Y160M2-2H | 43.2 | 86.4 | 22/Y180M-2H | 52 | 5 | 80 |

80CWZ-14 | 60 | 21 | 7.5/Y132S2-2H | 72 | 30.2 | 11/Y160M1-2H | 67 | 4 | 85 |

80CWZ-11 | 60 | 30 | 11/Y160M1-2H | 72 | 43.2 | 15/Y160M2-2H | 65 | 4 | 92 |

80CWZ-8 | 60 | 42 | 15/Y160M2-2H | 72 | 60.5 | 30/Y200L1-2H | 55 | 5 | 100 |

80CWZ-6 | 60 | 60 | 22/Y180M-2H | 72 | 86.4 | 37/Y200L2-2H | 54 | 5 | 100 |

80CWZ-5.5 | 60 | 75 | 30/Y200L1-2H | 72 | 108 | 45/Y225M-2H | 56 | 5 | 110 |

100CWZ-18 | 100 | 21 | 11/Y160M1-2H | 120 | 30.2 | 18.5/Y160L-2H | 68 | 5 | 125 |

100CWZ-14 | 100 | 30 | 15/Y160M2-2H | 120 | 43.2 | 30/Y200L1-2H | 65 | 5 | 128 |

100CWZ-11 | 100 | 42 | 22/Y180M-2H | 120 | 60.5 | 37/Y200L2-2H | 58 | 5 | 135 |

100CWZ-8 | 100 | 60 | 30/Y200L1-2H | 120 | 86.4 | 55/Y250M-2H | 55 | 4 | 152 |

100CWZ-6 | 100 | 85 | 45/Y225M-2H | 120 | 122.4 | 75/Y280S-2H | 59 | 5 | 165 |

80CWZ-4 | 25 | 25 | 5.5/Y132S-4H | 30 | 36 | 7.5/Y132M-4H | 42 | 2.3 | |

125CWZ-23.5 | 160 | 20 | 18.5/Y180M-4H | 192 | 28.8 | 30/Y200L-4H | 60 | 5 | |

125CWZ-16.5 | 160 | 32 | 30/Y200L-4H | 192 | 46 | 45/Y225M-4H | 63 | 5 | |

150CWZ-3.5 | 110 | 80 | 55/Y250M-4H | 130 | 115 | 90/Y280M-4H | 55 | 4.2 | |

150CWZ-13 | 200 | 20 | 22/Y180L-4H | 240 | 28.5 | 37/Y225S-4H | 60 | 5 | |

150CWZ-9 | 200 | 32 | 37/Y225S-4H | 240 | 43.8 | 55/Y250M-4H | 55 | 5 | |

150CWZ-7 | 200 | 45 | 45/Y225M-4H | 240 | 65 | 75/Y280S-4H | 65 | 5 | |

200CWZ-15 | 250 | 14 | 18.5/Y180M-4H | 300 | 20 | 30/Y200L-4H | 71 | 5 | |

200CWZ-9 | 300 | 45 | 75/Y280S-4H | 360 | 65 | 110/Y280M-4H | 70 | 5 | |

Note: the following optional220V/3KW single-phase motor.

The picture of pump