Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Pump Parts

-

Marine Automatic Control Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Self-priming Pump

Chemical pump

Urban pump

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: sales@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-18983389474

CSG Marine Vertical Fire Pump

Date:2022-07-06Views:

CSG Marine Vertical Fire Pump

Overview

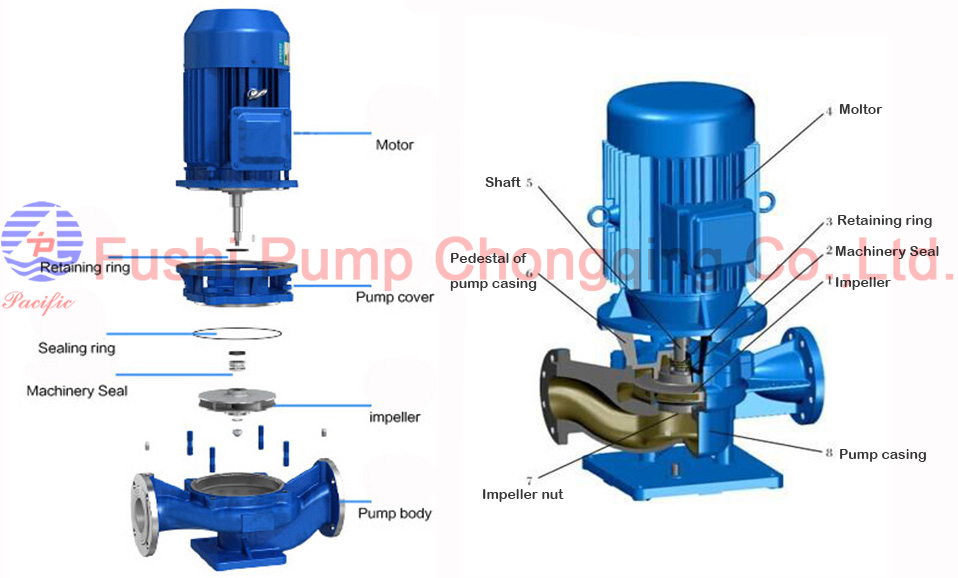

With advantages of simple structure, in strict accordance with international standards of ISO2858 and the new national standards for the design of successful energy efficient products,CSG type marine vertical fire pump which is a single-stage single suction centrifugal pump , for the transport of liquid temperature less than 100℃, the maximum working pressure of not more than1.6MPa in the water or the physical and chemical properties similar to clear liquid with,it can be designed as the same parameters of pump hot water (200℃), fire pump, chemical pumps, oil pumps, explosion-proof chemical pump, etc.

Product use

It is used for pressurized water supply in fire system pipelines. It can pressurize and supply water to fire system pipelines in various occasions, such as fire hydrant fire extinguishing system, automatic sprinkler fire extinguishing system and water spray fire extinguishing system.

Features

1. The pump has compact structure, small volume and beautiful appearance. Its vertical structure has a low center of gravity and the center of gravity in the center of the lower half of the pump, which enhances the running stability and life of the pump.

2. Easy to install. The inlet and outlet diameters are the same and are on the same centerline, which can be directly installed in any part of the pipeline like a valve. The motor and rain cover can be used outdoors. The pump is provided with mounting feet for stable installation of the pump.

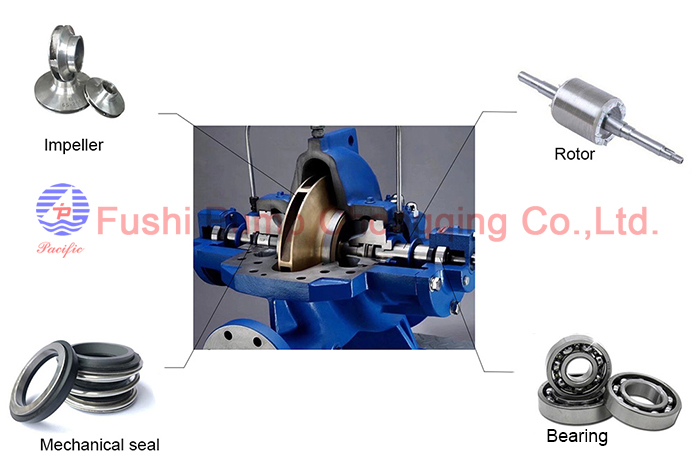

3. Smooth operation, low noise and high concentricity of components. The motor adopts low-noise bearings, and is equipped with a non-stop refueling device. The pump impeller has excellent dynamic and static balance, no vibration during operation, and improves the use environment.

4. No leakage. The shaft seal adopts corrosion-resistant hard alloy mechanical seal, which solves the problem of serious leakage of the packing seal of the centrifugal pump, prolongs the service life, and ensures the clean and tidy operating site.

5. Easy to maintain. There is no need to disassemble the pipeline, just remove the pump cover nut, take out the rotor and the transmission components for maintenance.

6. The pump can be installed vertically, horizontally or in multiple ways according to the on-site use conditions. According to the flow and lift requirements, the parallel and series methods are adopted to increase the required flow and lift.

Picture of the CSG marine vertical fire pump:

The excellent design of our company's engineers, the components made of high-quality materials can make the pump have longer service time, lower maintenance frequency, and higher operating stability in complex environments, but it can also generate different prices.If you need more details about this, you can click on the news or send an email to ask us

Model Explanation:

| Picture of CSG type marine vertical fire pump | Explanation detail-CSG ((R, H, B, BH)D、CSGB)50-160 (I) A(B, C) |

| CSG—CSGB single-stage single-inlet marine vertical centrifugal pump |

| R/H/B/BH—Hot-water pump/Chemical pump/Explosion proof pump/Non-explosive chemical pump | |

| D—Slow Speed of revolution | |

| 50—Inlet and outlet diameter 50 mm | |

| 160—Nominal diameter of impeller 160mm | |

| I—Flow classification | |

| A(B, C)—Impeller processed with 1(2, 3)cutting |

Parameter of CSG marine vertical fire pump:

(In addition, please provide the parameter of the marine pump you need and we can customize the suitable type for you.)

Photo of CSG marine vertical fire pump:

Application of CSG marine vertical fire pump:

Precautions for use

1. The maximum working pressure of the pump and the connected pipeline is ≤1.6MPa, and the pressure at the suction port of the pump + the pump head is ≤1.6Mpa. (If the working pressure of the pump system is greater than 1.6MPa, it should be put forward separately when ordering, so that we can use cast steel for the over-current parts and connecting parts of the pump during manufacture).

2. The ambient temperature does not exceed 50°C, the altitude does not exceed 1000 meters, and the relative humidity does not exceed 95%.

3. The conveying medium is clear water or other liquids with similar physical and chemical properties to clear water. (The conveying medium contains fine particles, which should be specified separately when ordering, so that we can assemble the wear-resistant mechanical seal.)

4. Before installing the pump, carefully check whether there are hard objects (such as stones, iron particles, etc.) in the pump flow channel that affect the operation of the pump, so as to avoid damage to the impeller and pump body when the pump is running.

5. The weight of the pipeline should not be added to the pump during installation, and there should be their own support bodies to avoid the deformation of the pump and affect the running performance and life.

6. The anchor bolts must be tightened during installation to avoid the impact of vibration on the pump performance during startup.

7. For the convenience of maintenance and safe use, a regulating valve is installed on the inlet and outlet pipelines of the pump and a pressure gauge is installed near the pump outlet to ensure the operation within the rated head and flow range, to ensure the normal operation of the pump and the growth of the pump. service life of the pump.

8. After installation, turn the pump shaft, the impeller should have no friction noise or stuck phenomenon, otherwise the pump should be disassembled to check the cause.