Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

CQB Series Magnetic Drive Centrifugal Pumps

Date:2025-04-10Views:

CQB Series Magnetic Drive Centrifugal Pumps

Overview

Magnetic drive centrifugal pumps (referred to as "magnetic pumps") are typically composed of an electric motor, a magnetic coupling, and a corrosion-resistant centrifugal pump. Their core feature is the use of a magnetic coupling for power transmission, ensuring complete leak-free operation. When the motor drives the external magnetic assembly of the coupling to rotate, magnetic lines of force pass through the air gap and isolation sleeve, acting on the internal magnetic assembly to synchronize the pump rotor with the motor, transmitting torque without mechanical contact. At the power input end of the pump shaft, the liquid is enclosed in a stationary isolation sleeve, eliminating dynamic seals and achieving zero leakage.

Developed by the National Magnetic Pump Joint Design Group, the CQ series magnetic pumps are new-generation, fully sealed, corrosion-resistant pumps compliant with JB/T7742-1995 standards.

Applications:

Ideal for industries including petroleum, chemical, pharmaceutical, metallurgy, electroplating, environmental protection, food processing, film processing, water treatment, and national defense.

Suitable for transporting flammable, explosive, volatile, toxic, rare/valuable liquids, and various corrosive media.

Operational parameters:

Suction pressure ≤ 0.2MPa; Maximum working pressure: 1.6MPa

Temperature ≤ 100°C; Density ≤ 1600kg/m³; Viscosity ≤ 30×10⁻⁶m²/S (liquids free of hard particles and fibers)

Model Explanation: CQB50-32-160

CQ: Magnetic Drive Centrifugal Pump

B: Wetted parts material (metal or thermosetting plastic)

50: Suction Port Diameter (mm)

32: Discharge Port Diameter (mm)

160: Nominal Impeller Diameter (mm)

Structural Specifications

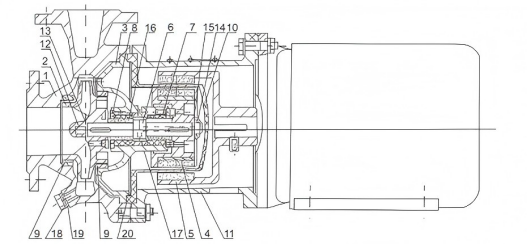

1.Pump Casing;2.Impeller;3.Bearing Housing;4.Internal Magnetic Assembly;5.External Magnetic Assembly;6.Pump Shaft;7.Bearings;8.Front/Back Thrust Rings;9.Sealing Plate;10.Isolation Sleeve;11.Connecting Bracket;12.Impeller Nut;13.Lock Washer;14.Nut;15.Washer;16.Shaft Sleeve;17.Positioning Sleeve;18.Pipe Plug;19, 20. Washers

Performance Parameters

Model

| Capacity (m³h) | Head (m) | Speed (r/min) | Efficiency (%) | Motor Model

| Power (KW) |

CQB32-20-125 | 3.2 | 20 | 2900 | 35 | YB802-2 | 1.1 |

CQB32-20-160 | 3.2 | 32 | 2900 | 35 | YB90S-2 | 1.5 |

CQB40-25-105 | 6.3 | 12.5 | 2900 | 45 | YB802-2 | 1.1 |

CQB40-25-125 | 6.3 | 20 | 2900 | 42 | YB90L-2 | 22 |

CQB40-25-160 | 6.3 | 32 | 2900 | 35 | YB100L-2 | 3 |

CQB40-25-200 | 6.3 | 50 | 2900 | 28 | YB132S1-2 | 5.5 |

CQB50-40-85 | 12.5 | 8 | 2900 | 56 | YB802-2 | 1.1 |

CQB50-32-105 | 12.5 | 12.5 | 2900 | 54 | YB90L-2 | 22 |

CQB50-32-125 | 12.5 | 20 | 2900 | 50 | YB100L-2 | 3 |

CQB50-32-160 | 12.5 | 32 | 2900 | 46 | YB112M-2 | 4 |

CQB50-32-200 | 12.5 | 50 | 2900 | 39 | YB132S2-2 | 7.5 |

CQB50-32-250 | 12.5 | 80 | 2900 | 30 | YB160L-2 | 18.5 |

CQB65-50-125 | 25 | 20 | 2900 | 58 | YB132S1-2 | 5.5 |

CQB65-50-160 | 25 | 32 | 2900 | 56 | YB132S2-2 | 7.5 |

CQB65-40-200 | 25 | 50 | 2900 | 49 | YB160M-2 | 15 |

CQB65-40-250 | 25 | 80 | 2900 | 46 | YB180M-2 | 22 |

COB80-65-125 | 50 | 20 | 2900 | 66 | YB132S2-2 | 7.5 |

COB80-65-160 | 50 | 32 | 2900 | 64 | YB160M-2 | 5 |

CQB80-50-200 | 50 | 50 | 2900 | 60 | YB160L-2 | 18.5 |

CQB80-50-250 | 50 | 80 | 2900 | 55 | YB200L1-2 | 30 |

CQB100-80-125 | 100 | 20 | 2900 | 72 | YB160M-2 | 15 |

CQB100-80-160 | 100 | 32 | 2900 | 70 | YB160M-2 | 22 |

CQB100-65-200 | 100 | 50 | 2900 | 68 | YB200L1-2 | 30 |

CQB100-65-250 | 100 | 80 | 2900 | 64 | YB225M-2 | 45 |

Note: All specifications are available with explosion-proof motors.