Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Industrial Pumps

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: Sales1@fspumps.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

CLH Marine Vertical Sewage Pump

Date:2025-03-07Views:

CLH Marine Vertical Sewage Pump

Overview

CLH type pump is in accordance with ISO international standards and the design of a single stage, single suction, level inlet and outlet of the centrifugal pump, the motor shaft and the pump shaft flange connection is convenient to disassemble. Can be used as various ship ballast pump, bilge pump, drainage pump, cooling pump, fire pump, and is also suitable for the petrochemical pipe City, high-rise building water and circulation system of the booster pump. Transmission fluid temperature not exceeding 75℃.

Model Explanation CLH 50-160 (I) A(B, C)

CLH—Marine vertical sea water pump

50—Inlet and outlet diameter 50 mm

160—Nominal diameter of impeller 160mm

I—Flow classification

A(B, C)—Impeller processed with 1(2, 3)cutting

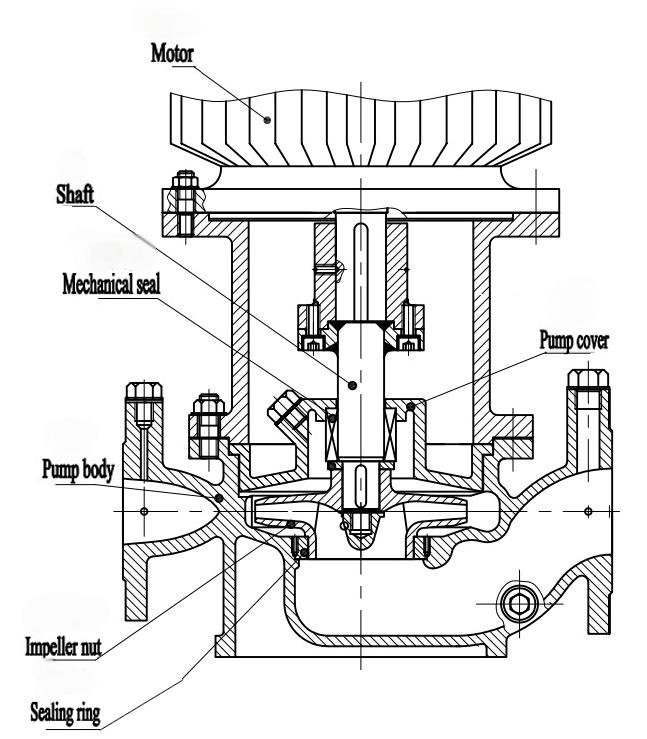

Structural Specifications

CLH

Performance Parameter

CLH | 50HZ | 60HZ | 50HZ/60HZ | ||||||||

Type | Capacity (m3/h) | Head (m) | Speed (rpm) | Motor power (kW) | Weight (kg) | Capacity (m3/h) | Head (m) | Speed (rpm) | Motor power (kW) | (NPSH)r (m) | Efficiency (%) |

15-80 | 1.1 | 8.5 | 2900 | 0.18 | 17 | 1.3 | 12.2 | 3500 | 0.25 | 2.3 | 26 |

1.5 | 8 | 1.8 | 11.5 | 34 | |||||||

2 | 7 | 2.4 | 10.1 | 34 | |||||||

20-110 | 1.8 | 16 | 2900 | 0.37 | 25 | 2.2 | 23 | 3500 | 0.75 | 2.3 | 25 |

2.5 | 15 | 3 | 21.6 | 34 | |||||||

3.3 | 13.5 | 4 | 19.4 | 35 | |||||||

20-125 | 1.8 | 21 | 2900 | 0.75 | 35 | 2.2 | 30.2 | 3500 | 1.1 | 2.3 | 30 |

2.5 | 20 | 3 | 28.8 | ||||||||

3.3 | 18.6 | 4 | 26.8 | ||||||||

20-160 | 1.8 | 33 | 2900 | 1.1 | 29 | 2.2 | 47.5 | 3500 | 1.5 | 2.3 | 19 |

2.5 | 32 | 3 | 46.1 | 25 | |||||||

3.3 | 30 | 4 | 43.2 | 23 | |||||||

25-110 | 2.8 | 16 | 2900 | 0.55 | 26 | 3.4 | 23 | 3500 | 0.75 | 2.3 | 34 |

4 | 15 | 4.8 | 21.6 | 42 | |||||||

5.2 | 13.5 | 6.2 | 19.4 | 41 | |||||||

25-125 | 2.8 | 20.6 | 2900 | 0.75 | 28 | 3.4 | 29.7 | 3500 | 1.1 | 2.3 | 28 |

4 | 20 | 4.8 | 28.8 | 36 | |||||||

5.2 | 18 | 6.2 | 25.9 | 35 | |||||||

25-125A | 2.5 | 17 | 2900 | 0.75 | 27 | 3 | 24.5 | 3500 | 1.1 | 2.3 | 35 |

3.6 | 16 | 4.3 | 23 | ||||||||

4.6 | 14.4 | 5.5 | 20.7 | ||||||||

25-160 | 2.8 | 33 | 2900 | 1.5 | 39 | 3.4 | 47.5 | 3500 | 2.2 | 2.3 | 24 |

4 | 32 | 4.8 | 46.1 | 32 | |||||||

5.2 | 30 | 6.2 | 43.2 | 33 | |||||||

25-160A | 2.6 | 28.5 | 2900 | 1.1 | 34 | 3.1 | 41 | 3500 | 1.5 | 2.3 | 22 |

3.7 | 28 | 4.4 | 40.3 | 31 | |||||||

4.9 | 26 | 5.9 | 37.4 | 29 | |||||||

32-100 | 4.5 | 12.5 | 2900 | 0.55 | 27 | 5.4 | 18 | 3500 | 0.75 | 2 | 44 |

32-100(I) | 3.75 | 13.2 | 2900 | 0.75 | 32 | 4.5 | 19 | 3500 | 1.1 | 2 | 48 |

5.3 | 12.5 | 6.4 | 18 | 54 | |||||||

8.3 | 11.3 | 10 | 16.3 | 53 | |||||||

32-125 | 3.5 | 22 | 2900 | 0.75 | 28 | 4.2 | 31.7 | 3500 | 1.1 | 2.3 | 40 |

5 | 20 | 6 | 28.8 | 44 | |||||||

6.5 | 18 | 7.8 | 25.9 | 42 | |||||||

32-125A | 3.1 | 17.6 | 2900 | 0.55 | 28 | 3.7 | 25.3 | 3500 | 0.75 | 2.3 | 39 |

4.5 | 16 | 5.4 | 23 | 43 | |||||||

5.8 | 14.4 | 7 | 20.7 | 41 | |||||||

32-160 | 5 | 32 | 2900 | 1.5 | 39 | 6 | 46.1 | 3500 | 2.2 | 2.3 | 44 |

32-160A | 4 | 25 | 2900 | 1.1 | 38 | 4.8 | 36 | 3500 | 1.5 | 2 | 34 |

32-160(I) | 4.4 | 33.2 | 2900 | 2.2 | 47 | 5.3 | 47.8 | 3500 | 3 | 2 | 34 |

6.3 | 32 | 7.6 | 46.1 | 40 | |||||||

8.3 | 30.2 | 10 | 43.5 | 42 | |||||||

32-200 | 4.5 | 50 | 2900 | 3 | 55 | 5.4 | 72 | 3500 | 4 | 2 | 32 |

32-200A | 2.8 | 44.6 | 2900 | 3 | 74 | 3.4 | 64.2 | 3500 | 4 | 2 | 34 |

4 | 44 | 4.8 | 63.4 | 40 | |||||||

5.2 | 42.7 | 6.2 | 61.5 | 42 | |||||||

32-200(I) | 4.4 | 50.5 | 2900 | 4 | 43 | 5.3 | 72.7 | 3500 | 5.5 | 2 | 26 |

6.3 | 50 | 7.6 | 72 | 33 | |||||||

8.3 | 48 | 10 | 69.1 | 35 | |||||||

40-100 | 4.4 | 13.2 | 2900 | 0.55 | 32 | 5.3 | 19 | 3500 | 0.75 | 2.3 | 48 |

6.3 | 12.5 | 7.6 | 18 | 54 | |||||||

8.3 | 11.3 | 10 | 16.3 | 53 | |||||||

40-100A | 3.9 | 10.6 | 2900 | 0.37 | 32 | 4.7 | 15.3 | 3500 | 0.55 | 2.3 | 46 |

5.6 | 10 | 6.7 | 14.4 | 52 | |||||||

7.4 | 9 | 8.9 | 13 | 51 | |||||||

40-125 | 4.4 | 21 | 2900 | 1.1 | 34 | 5.3 | 30.2 | 3500 | 1.5 | 2.3 | 41 |

6.3 | 20 | 7.6 | 28.8 | 46 | |||||||

8.3 | 18 | 10 | 25.9 | 43 | |||||||

40-125A | 3.9 | 17.6 | 2900 | 0.75 | 33 | 4.7 | 25.3 | 3500 | 1.1 | 2.3 | 40 |

5.6 | 16 | 6.7 | 23 | 45 | |||||||

7.4 | 14.4 | 8.9 | 20.7 | 41 | |||||||

40-160 | 4.4 | 33 | 2900 | 2.2 | 47 | 5.3 | 47.5 | 3500 | 3 | 2.3 | 35 |

6.3 | 32 | 7.6 | 46.1 | 40 | |||||||

8.3 | 30 | 10 | 43.2 | 40 | |||||||

40-160A | 4.1 | 29 | 2900 | 1.5 | 43 | 4.9 | 41.8 | 3500 | 2.2 | 2.3 | 34 |

5.9 | 28 | 7.1 | 40.3 | 39 | |||||||

7.8 | 26.3 | 9.4 | 37.9 | 39 | |||||||

40-160B | 3.8 | 25.5 | 2900 | 1.1 | 38 | 4.6 | 36.7 | 3500 | 1.5 | 2.3 | 34 |

5.5 | 24 | 6.6 | 34.6 | 38 | |||||||

7.2 | 22.5 | 8.6 | 32.4 | 37 | |||||||

40-200 | 4.4 | 51 | 2900 | 4 | 74 | 5.3 | 73.4 | 3500 | 5.5 | 2.3 | 26 |

6.3 | 50 | 7.6 | 72 | 33 | |||||||

8.3 | 48 | 10 | 69.1 | 32 | |||||||

40-200A | 4.1 | 45 | 2900 | 3 | 62 | 4.9 | 64.8 | 3500 | 4 | 2.3 | 26 |

5.9 | 44 | 7.1 | 63.4 | 31 | |||||||

7.8 | 42 | 9.4 | 60.5 | 30 | |||||||

40-200B | 3.7 | 38 | 2900 | 2.2 | 52 | 4.4 | 54.7 | 3500 | 3 | 2.3 | 24 |

5.3 | 36 | 6.4 | 51.8 | 29 | |||||||

7 | 34.5 | 8.4 | 49.7 | 28 | |||||||

40-250 | 4.4 | 82 | 2900 | 7.5 | 105 | 5.3 | 118.1 | 3500 | 15 | 2.3 | 24 |

6.3 | 80 | 7.6 | 115.2 | 28 | |||||||

8.3 | 74 | 10 | 106.6 | 28 | |||||||

40-250A | 4.1 | 72 | 2900 | 7.5 | 98 | 4.9 | 103.7 | 3500 | 15 | 2.3 | 24 |

5.9 | 70 | 7.1 | 100.8 | 28 | |||||||

7.8 | 65 | 9.4 | 93.6 | 27 | |||||||

40-250B | 3.8 | 61.5 | 2900 | 5.5 | 77 | 4.6 | 88.6 | 3500 | 7.5 | 2.3 | 23 |

5.5 | 60 | 6.6 | 86.4 | 27 | |||||||

7 | 56 | 8.4 | 80.6 | 26 | |||||||

40-100(I) | 8.8 | 13.2 | 2900 | 1.1 | 34 | 10.6 | 19 | 3500 | 1.5 | 2.3 | 55 |

12.5 | 12.5 | 15 | 18 | 62 | |||||||

16.3 | 11.3 | 19.6 | 16.3 | 60 | |||||||

40-100(I)A | 8 | 10.6 | 2900 | 0.75 | 32 | 9.6 | 15.3 | 3500 | 1.1 | 2.3 | 53 |

11 | 10 | 13.2 | 14.4 | 60 | |||||||

14.5 | 9 | 17.4 | 13 | 58 | |||||||

40-125(I) | 8.8 | 21.2 | 2900 | 1.5 | 38 | 10.6 | 30.5 | 3500 | 2.2 | 2.3 | 49 |

12.5 | 20 | 15 | 28.8 | 58 | |||||||

16.3 | 17.8 | 19.6 | 25.6 | 57 | |||||||

40-125(I)A | 8 | 17 | 2900 | 1.1 | 33 | 9.6 | 24.5 | 3500 | 1.5 | 2.3 | 48 |

11 | 16 | 13.2 | 23 | 57 | |||||||

14.5 | 14 | 17.4 | 20.2 | 56 | |||||||

40-160(I) | 8.8 | 33 | 2900 | 3 | 56 | 10.6 | 47.5 | 3500 | 4 | 2.3 | 45 |

12.5 | 32 | 15 | 46.1 | 52 | |||||||

16.3 | 30 | 19.6 | 43.2 | 51 | |||||||

40-160(I)A | 8.2 | 29 | 2900 | 2.2 | 47 | 9.8 | 41.8 | 3500 | 3 | 2.3 | 44 |

11.7 | 28 | 14 | 40.3 | 51 | |||||||

15.2 | 26 | 18.2 | 37.4 | 50 | |||||||

40-160(I)B | 7.3 | 23 | 2900 | 1.5 | 43 | 8.8 | 33.1 | 3500 | 2.2 | 2.3 | 43 |

10.4 | 22 | 12.5 | 31.7 | 50 | |||||||

13.5 | 20.5 | 16.2 | 29.5 | 49 | |||||||

40-200(I) | 8.8 | 51.2 | 2900 | 5.5 | 85 | 10.6 | 73.7 | 3500 | 7.5 | 2.3 | 38 |

12.5 | 50 | 15 | 72 | 46 | |||||||

16.3 | 48 | 19.6 | 69.1 | 46 | |||||||

40-200(I)A | 8.3 | 45 | 2900 | 4 | 75 | 10 | 64.8 | 3500 | 5.5 | 2.3 | 37 |

11.7 | 44 | 14 | 63.4 | 45 | |||||||

15.3 | 42 | 18.4 | 60.5 | 45 | |||||||

The picture of pump