Marine pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Fresh Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

-

Marine Pump Parts

-

Marine Automatic Control Pump

-

Marine Centrifugal Pump

-

Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Cooling Water Pump

Chemical pump

Urban pump

Other pump

Civil Pump

Submersible Pump

Contact us

Fushi Pump Chongqing Co., Ltd

Address: No. 11, Tianxing Avenue, ShuangQiao Industrial Park, Chongqing,China

E-mail: material@hiseamarine.com

Tel: +86-23-67956606

Fax: +86-23-67956622

Mobil: +86-19332298771

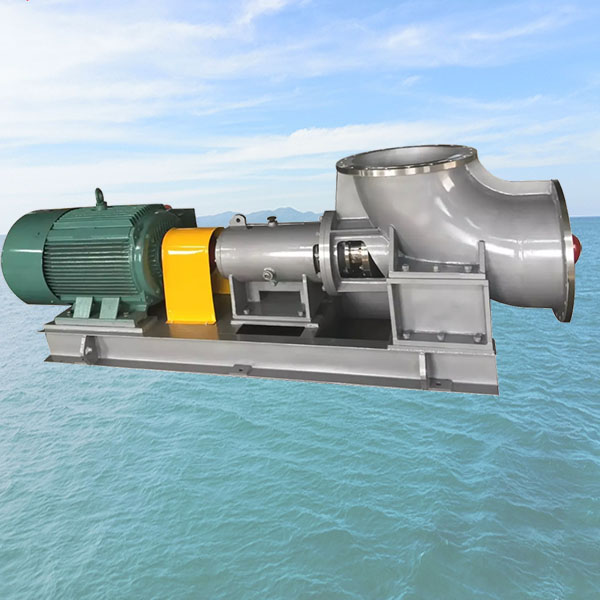

HZ Chemical Axial Flow Pumps

Date:2025-03-14Views:

HZ Chemical Axial Flow Pumps

Introduction:

HZ series imposed-circulating pump is designed by GB/T13008-1992 and developed by ourselves referring to the advanced pump product home and abroad according to the features of alkali, salt, criic acid and Na2SO4 industries. The series of products have been recongnized since 1996 when it was brought into the market.

Performance:

| Flow | up to 30000m3/h |

| Head | up to 10m |

| Pressure | up to 1.6MPa |

| Temperature | up to 180℃ |

Applications:

Mainly applied in the imposed circulation of various of crystable saturated solution in the course of evaporation/concentration in alakli, salt, citric acid and Na2SO4 Manufacture industries.

Structural Features:

HZ imposed circulation pump has two kinds structures one is typically applicable for the installation supported by ground. It has axial suction and radial discharge. In order to repair easily, the rotation parrts composed by impeller shaft can be drawn from pump casing. There is no need to disassemble the suction and discharge piping. The other is half-suspending structure applicable for the pump part suspending on the piping and the motor installed on the ground. In order to reduce the weight of the part suspending, front-open structure is taken.

The impeller of the imposed circulation pump locates in the impeller housing which clearance can be adjusted accoeding to impeller's factual location and improve the operation efficiency.

There are two seal structures: double-action stuffing box(operation stuffing seal and shutdown stuffing seal are respectively assembled) and the double-end cartridge mechanical seal(which is propitious to seal's assemble&disassembly).

Bearing is lubracated by oil with a cooling device to cool the oil so that the operation environment of the bearing can be changed.

The performance of the pump can be adjusted by changing impeller's emplacement angle and pump speed according to technology requirement to satisfy different evaporation device.

The parts contacting with the fluid are made of 304, 304L, 316, 316L and 804 etc material. 22 types of materail can be selected in our plant, which is as per different medium.